1. Rolling Friction and Energy Loss

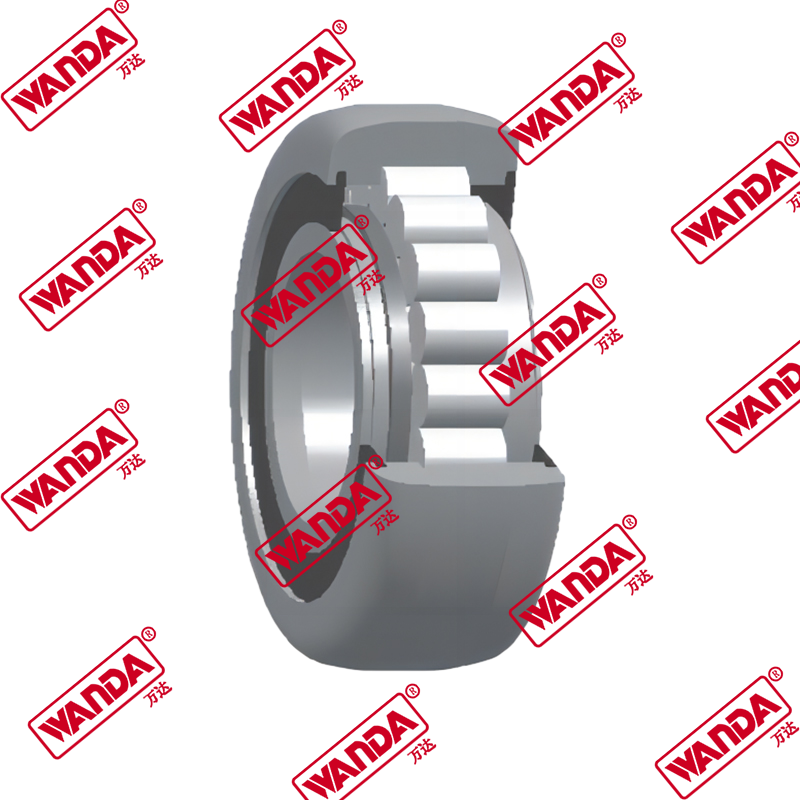

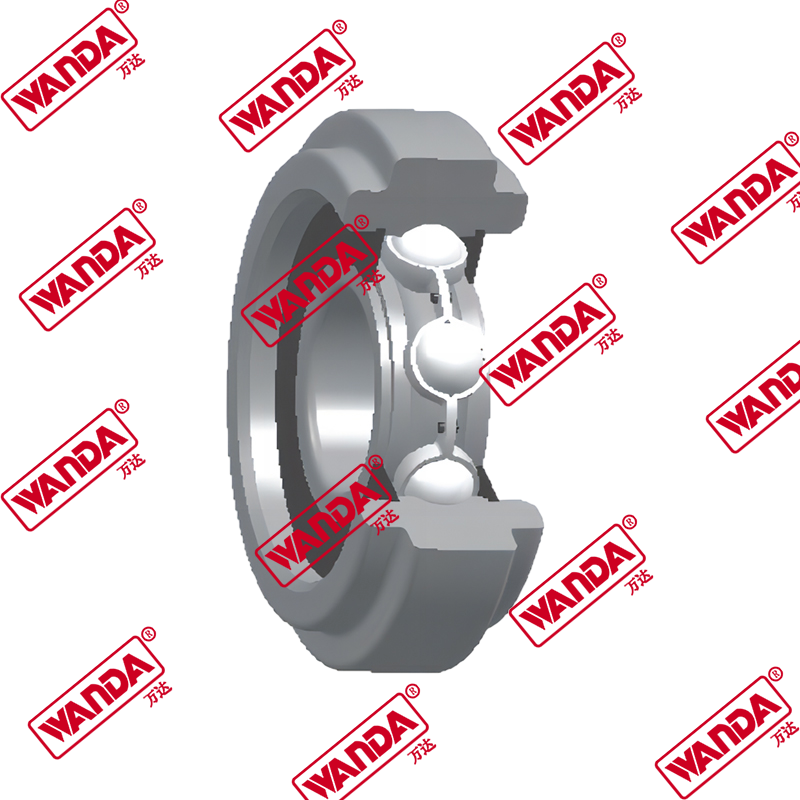

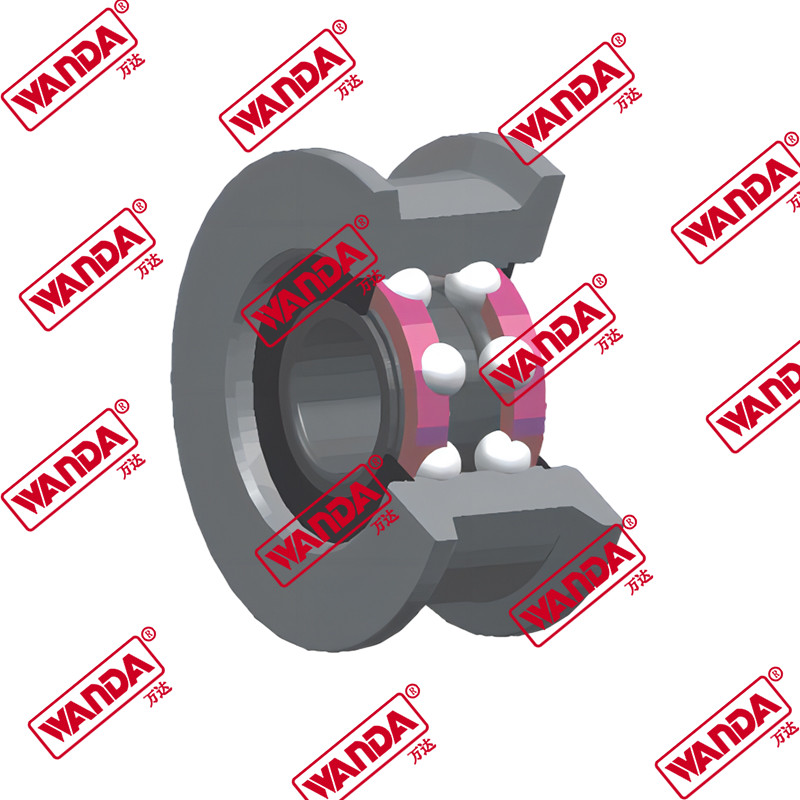

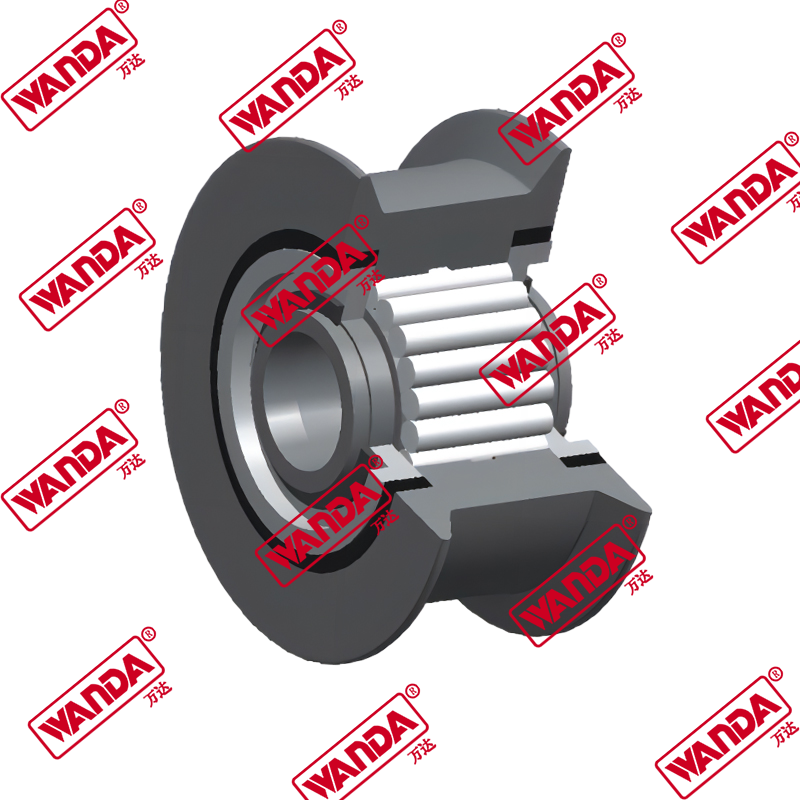

Bearings operate on the principle of rolling friction, utilizing rolling elements such as steel balls or rollers between inner and outer rings. Compared to traditional sliding friction, rolling friction significantly reduces energy loss. This design not only minimizes heat and noise generated by friction but also enhances bearing efficiency. High efficiency means that under the same input power, mechanical equipment can generate greater output efficiency, thereby saving energy costs and reducing environmental impact.

2. Vibration and Shock Control

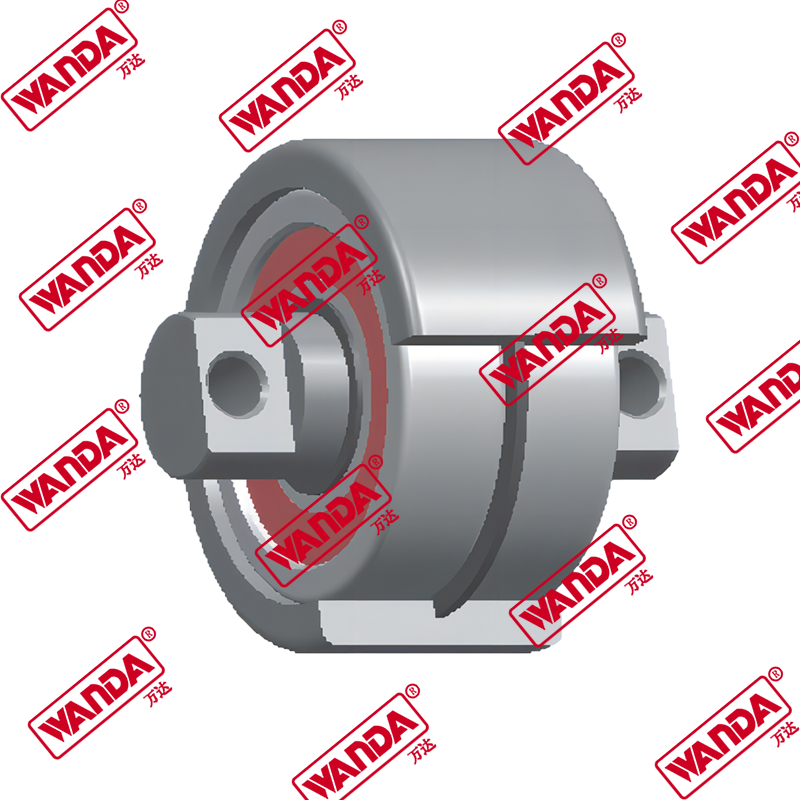

Well-designed bearings effectively reduce vibration and shock within mechanical systems. Vibrations and shocks not only affect equipment stability and smooth operation but also accelerate wear on bearings and other mechanical components. By minimizing these adverse effects, bearings not only extend their own lifespan but also improve the reliability and stability of the entire mechanical system.

3. Lifespan and Reliability

The lifespan of bearings depends on several factors, including material selection, manufacturing processes, lubrication methods, etc. High-quality bearings use high-strength bearing steel and undergo precise machining and heat treatment to ensure long-term durability. Stable-running bearings reduce friction and wear, thereby extending their lifespan and reducing maintenance requirements and downtime, ultimately enhancing equipment reliability and operational efficiency.

4. Consistency of Performance and Predictive Maintenance

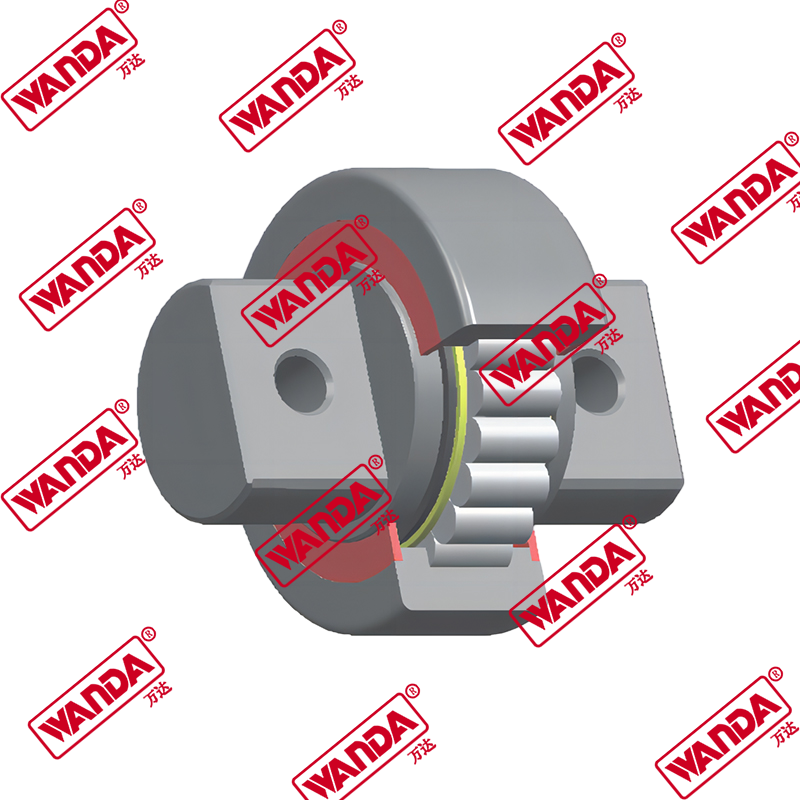

Stable-running bearings provide consistent performance and predictive maintenance capabilities. This means that during equipment operation, there is minimal variation in bearing performance, allowing operators to reliably predict and plan maintenance to avoid sudden failures and damage, thus reducing maintenance costs and the risk of production interruptions.

5. Environmental Adaptability

Different working environments impose varying demands on bearings, such as high temperature, low temperature, high speed, high load, etc. Bearings that run stably typically exhibit good environmental adaptability, maintaining their performance and reliability under various harsh conditions, thereby meeting diverse industrial application requirements.

In summary, the stability of bearing operation is not just a technical characteristic; it directly impacts the performance, efficiency, and reliability of the entire mechanical system. By selecting and optimizing appropriate bearings, equipment efficiency can be significantly enhanced, operational costs reduced, and the competitiveness and continuous operation capability of industrial equipment strengthened.