1. Structure and design of forklift gantry sprocket bearing

As the name implies, the forklift gantry sprocket bearing is a key component located on the forklift gantry (i.e., the gantry system). It is not only the cornerstone for supporting the weight of the entire gantry, but also the transmission core for realizing the vertical lifting movement of the gantry. This component is usually made of high-strength alloy materials and is precisely processed to ensure that it can still maintain a high degree of stability and durability when bearing heavy loads.

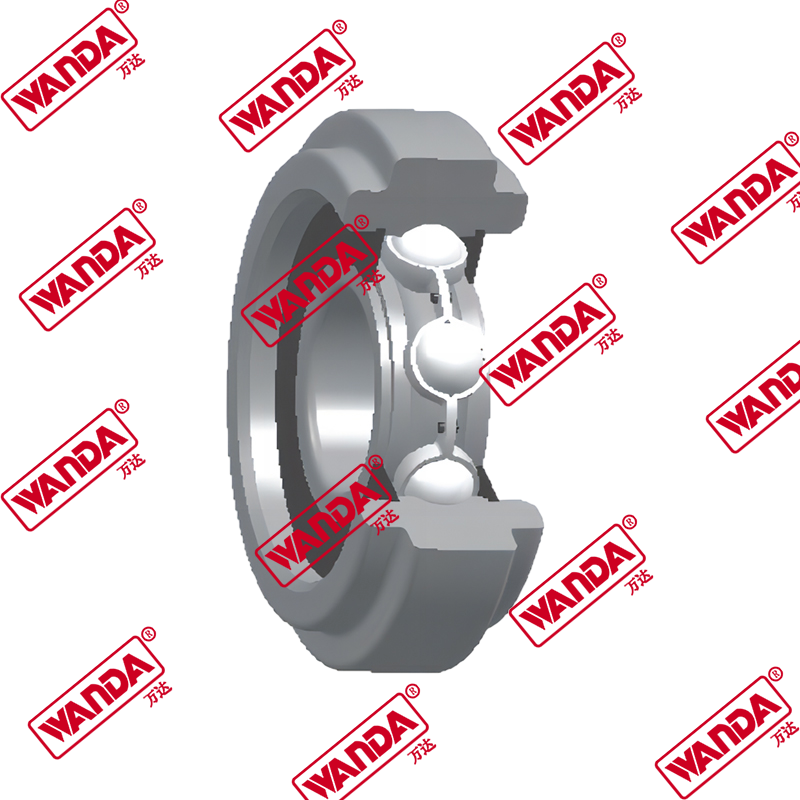

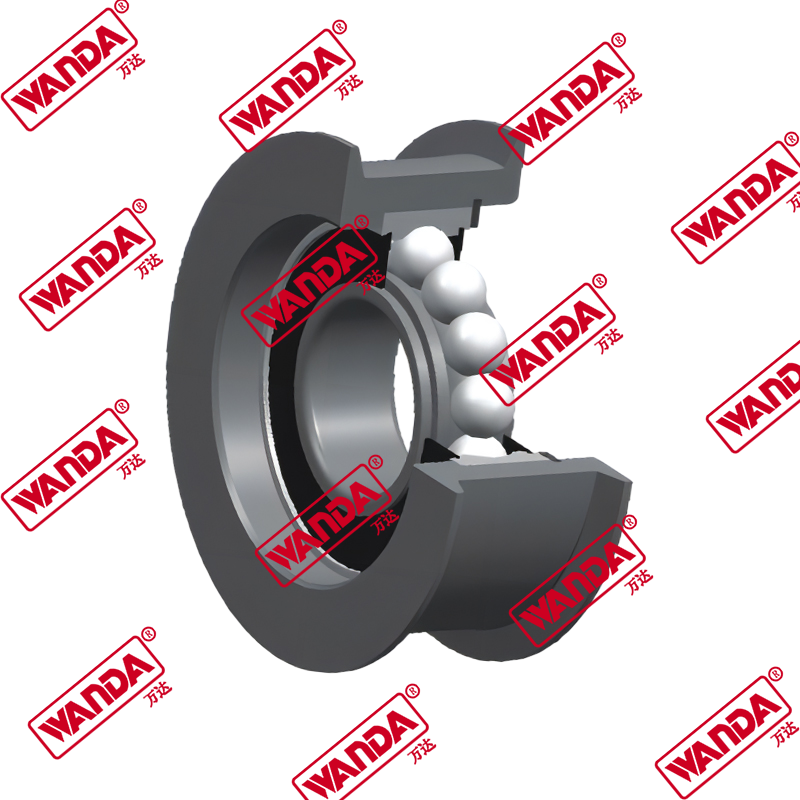

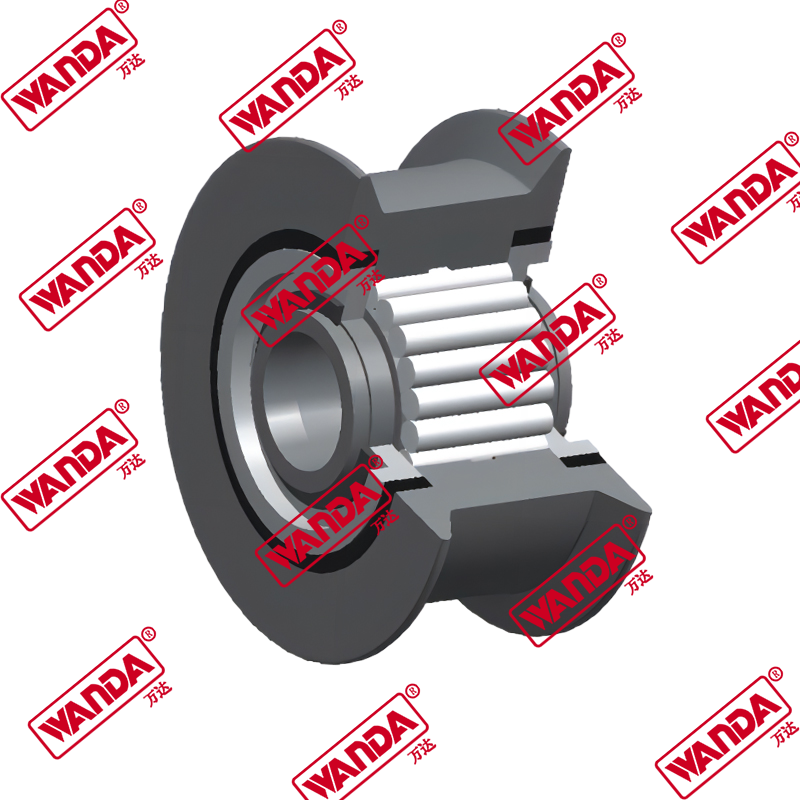

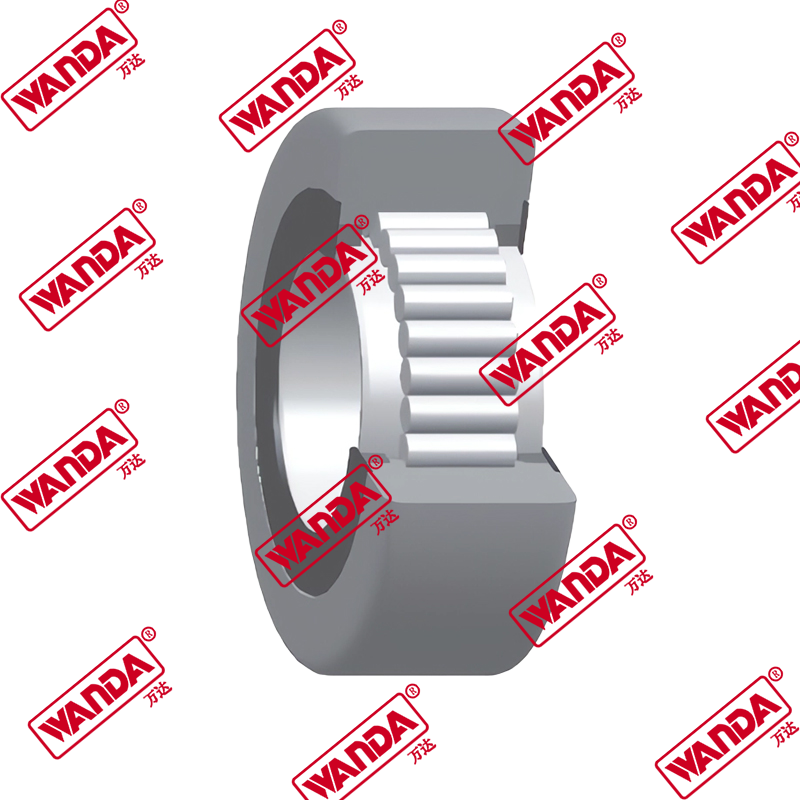

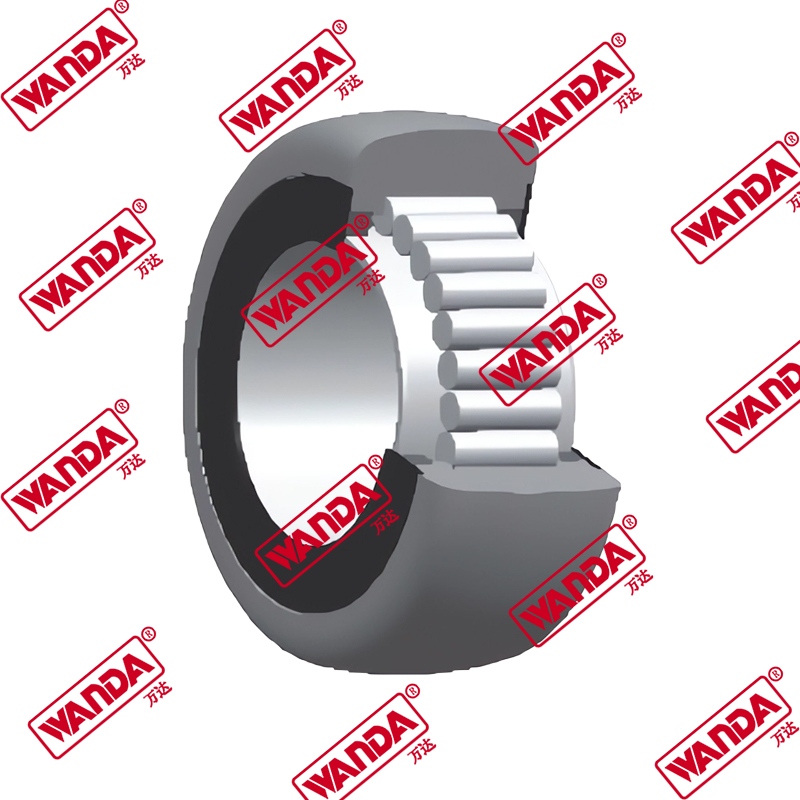

In terms of design, the gantry sprocket bearing adopts an optimized sprocket structure and a precise bearing configuration. The sprocket surface is specially treated to reduce the friction loss of the chain during the transmission process and improve the transmission efficiency. At the same time, the rolling contact design is adopted inside the bearing, which can more effectively disperse the load, reduce wear and extend the service life compared to sliding contact. This design not only ensures the smooth movement of the gantry in the vertical direction, but also greatly improves the overall reliability and safety of the system.

2. The dual role of support and transmission

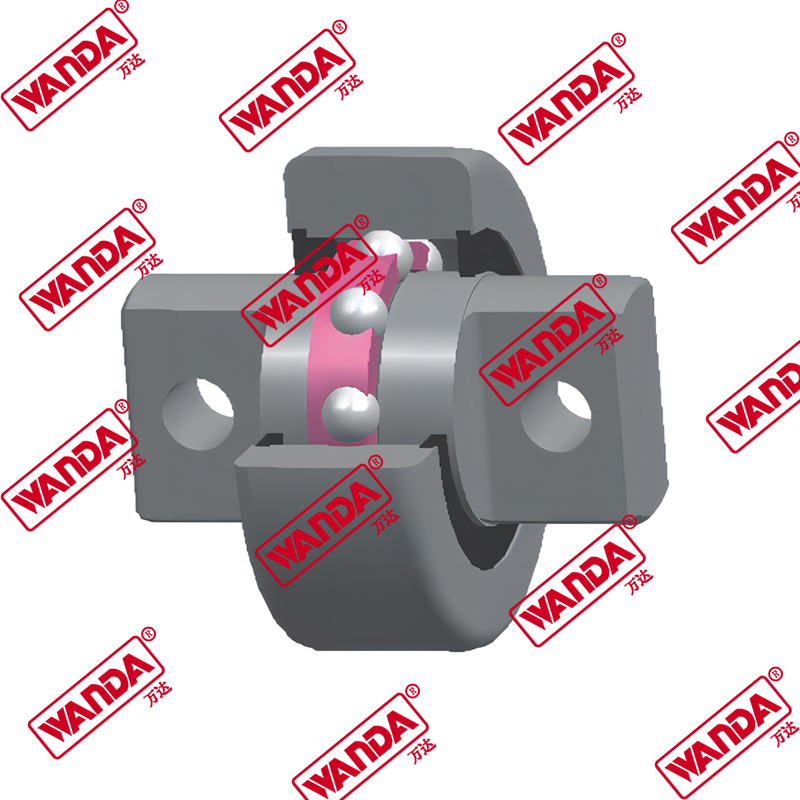

The core value of the forklift gantry sprocket bearing lies in its dual functions of support and transmission. On the one hand, as a supporting structure, it can effectively bear the full weight of the forklift mast and the goods loaded on it, ensuring that there will be no shaking or tilting during the operation, providing a stable and safe working environment for the operator. This feature is particularly important for forklifts operating in high-stack environments, as it is directly related to the safety and accuracy of cargo handling.

On the other hand, as part of the transmission system, the gantry sprocket bearing transmits power from the engine to the mast through the close cooperation of the chain to realize the lifting and lowering operation of the fork frame. The selection and layout design of the chain have been carefully calculated to ensure the rapid response and smooth progress of the lifting action. Whether it is lifting the goods from the ground to the high-level shelf or placing the goods safely on the ground from a height, it can be easily completed, greatly improving the efficiency of loading and unloading operations.

3. The key to improving the efficiency of loading and unloading operations

The efficient operation of the forklift gantry sprocket bearing directly promotes the significant improvement of the efficiency of loading and unloading operations. First, by optimizing the lifting speed, the time cost of a single operation is reduced, especially when handling large quantities of goods or urgent orders, this efficiency improvement is particularly obvious. Secondly, stable support and precise transmission control reduce safety risks during operation, reduce downtime caused by failures, and further improve overall operational efficiency. In addition, good wear resistance and durability ensure long-term stable operation of the equipment, reduce maintenance costs and downtime, and provide strong guarantee for the company's continuous production.