1. Reasonable operation of forklift to reduce the wear of Forklift Gantry Sprocket Bearing

Smooth driving

During the driving process of the forklift, the driver should maintain a stable driving habit and avoid sudden acceleration, sudden braking and sharp turns. These violent actions will cause the forklift to generate a large impact force, thereby increasing the wear of the bearing. Especially when carrying heavy objects, more attention should be paid to the smoothness of the operation to reduce the impact on the bearing.

Pay attention to the loading weight

The carrying capacity of the forklift is limited. Overloading will cause the overall structure of the forklift to be overstressed, and the pressure on the Forklift Gantry Sprocket Bearing will also increase accordingly. Therefore, when loading goods, it should be carried out strictly in accordance with the carrying capacity of the forklift to avoid overloading.

Choose the appropriate driving speed

Forklifts should choose the appropriate driving speed under different road conditions and working environments. On flat roads, the driving speed can be appropriately increased to improve working efficiency; on rugged roads or working environments that require frequent steering, the driving speed should be reduced to reduce the impact and wear on the bearings.

Maintain the correct driving posture

When driving a forklift, the driver should maintain the correct driving posture and avoid physical fatigue caused by maintaining the same posture for a long time. At the same time, pay attention to the surrounding environment to ensure that obstacles and pedestrians can be avoided in time during driving to reduce the occurrence of accidents.

2. Avoid excessive wear of the Forklift Gantry Sprocket Bearing during the use of the forklift

Regular lubrication

Lubrication is one of the effective means to reduce bearing wear. Regularly adding an appropriate amount of lubricating oil or grease to the Forklift Gantry Sprocket Bearing can keep the inside of the bearing clean and lubricated, reduce friction and wear. At the same time, the lubricating oil can also play a cooling and rust-proof role, extending the service life of the bearing.

Cleaning the bearing

Regularly cleaning the impurities and dirt around the Forklift Gantry Sprocket Bearing is also an important measure to reduce wear. During the cleaning process, a clean cloth or brush should be used to remove dust and oil from the bearing surface, and metal tools should be avoided to scratch the bearing surface. At the same time, attention should be paid to checking the sealing performance of the bearing to ensure that no foreign matter enters the inside of the bearing.

Inspection and adjustment

It is also necessary to regularly check the wear and tightness of the bearing. If the bearing is found to be abnormally worn or loose, it should be replaced or tightened in time. In addition, the installation position and clearance of the bearing should be checked to ensure that the bearing runs in the correct position with the correct clearance.

Avoid long-term continuous operation

Long-term continuous operation will cause overheating and increased wear of the forklift and bearings. Therefore, during the operation, the operation time and rest time should be reasonably arranged to avoid long-term continuous operation of the forklift. At the same time, after the operation, the forklift power should be turned off in time and allowed to cool naturally for a period of time.

Optimize the working environment

The working environment of the forklift also has a great impact on its performance and bearing wear. The ground should be kept flat, without potholes and sharp objects in the working area to reduce the bumps and impacts of the forklift during driving. At the same time, it should also be avoided to work in a humid and corrosive environment to reduce the corrosion and wear of the bearing.

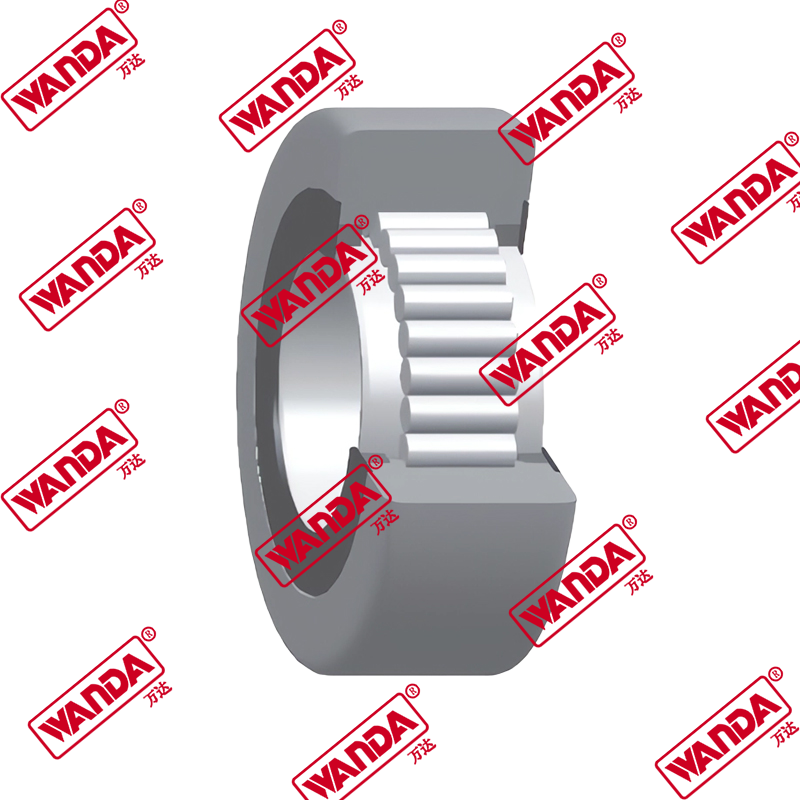

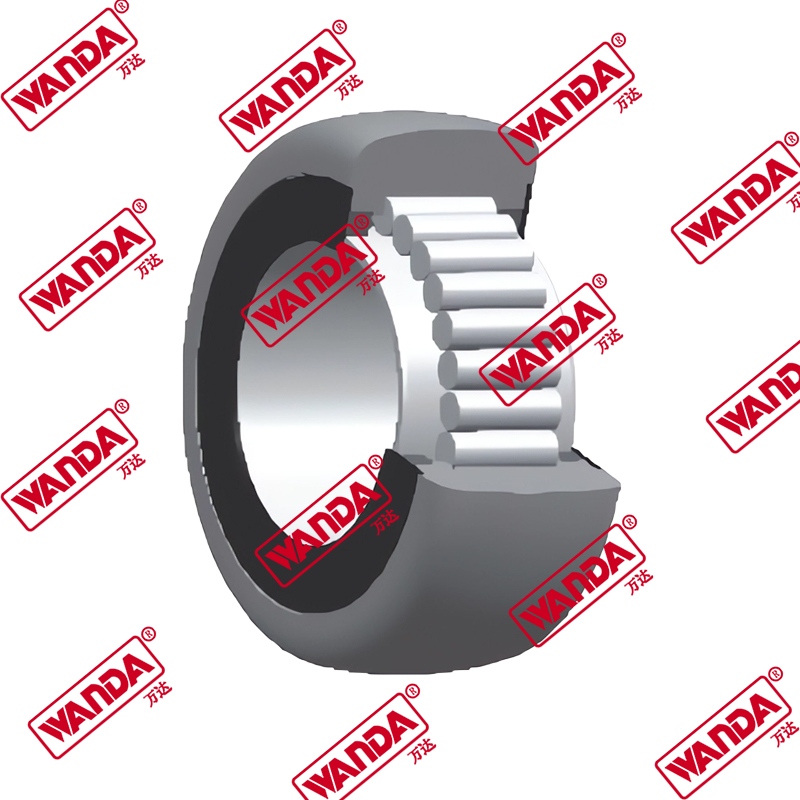

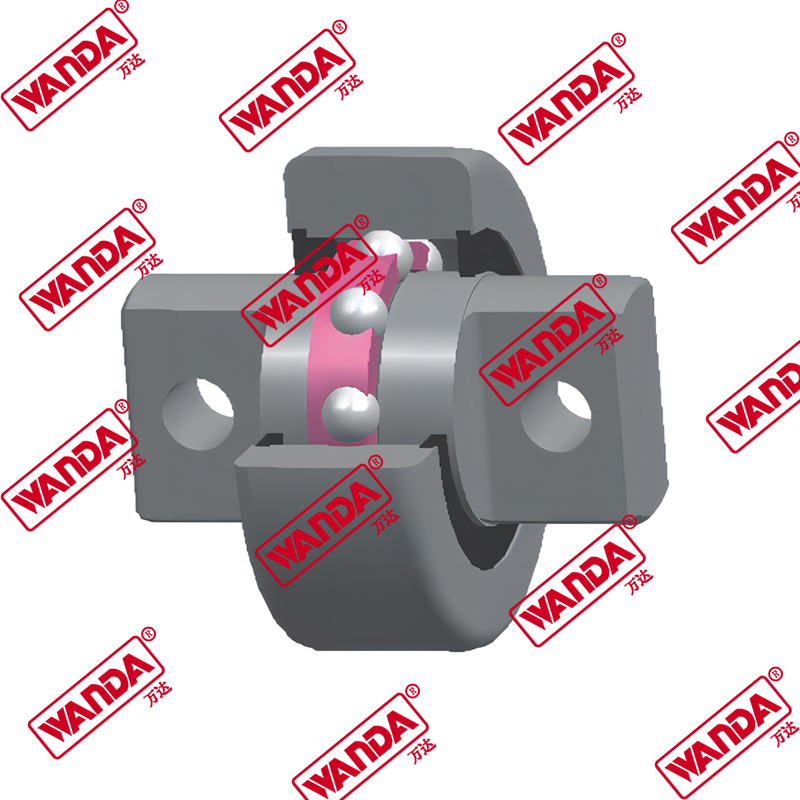

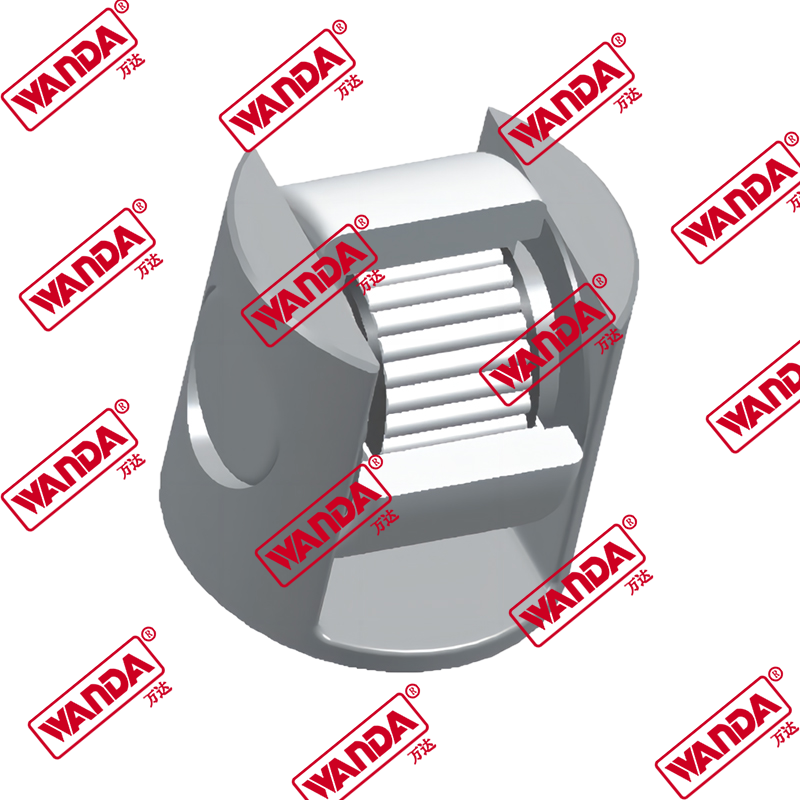

Choose high-quality accessories

When purchasing a forklift or replacing accessories, you should choose bearings and accessories with reliable quality and superior performance. High-quality bearings have better wear resistance and fatigue resistance, which can reduce the occurrence of wear and failure. At the same time, accessories suitable for the use environment and operation requirements of the forklift should be selected to improve its service life and performance.

Establish a maintenance system

In order to effectively extend the service life of the Forklift Gantry Sprocket Bearing and reduce wear, a complete maintenance system should be established. The system should include regular inspection, cleaning, lubrication and replacement steps, and clearly define the responsible person and execution time. At the same time, forklift drivers should also be trained and assessed regularly to improve their operating skills and maintenance awareness.