In busy warehouses, logistics centers and even various industrial sites, forklifts are the main force of material handling, and their stability and safety have always been the focus of people's attention. Especially when turning or driving on uneven roads, how to ensure the stability of the forklift body and prevent rollover has become an important issue in forklift design and manufacturing. Among them, the forklift side rollers play a vital role. They are like invisible guards, silently guarding the driving stability of the forklift.

Centrifugal force challenge in forklift turning

When the forklift is turning, due to the principles of physics, the body will be affected by centrifugal force and tend to tilt outward. This tilt not only affects the driver's control experience, but also may endanger the safety of the goods, and even cause serious accidents such as forklift rollover. In order to meet this challenge, forklift designers cleverly introduced the side roller design.

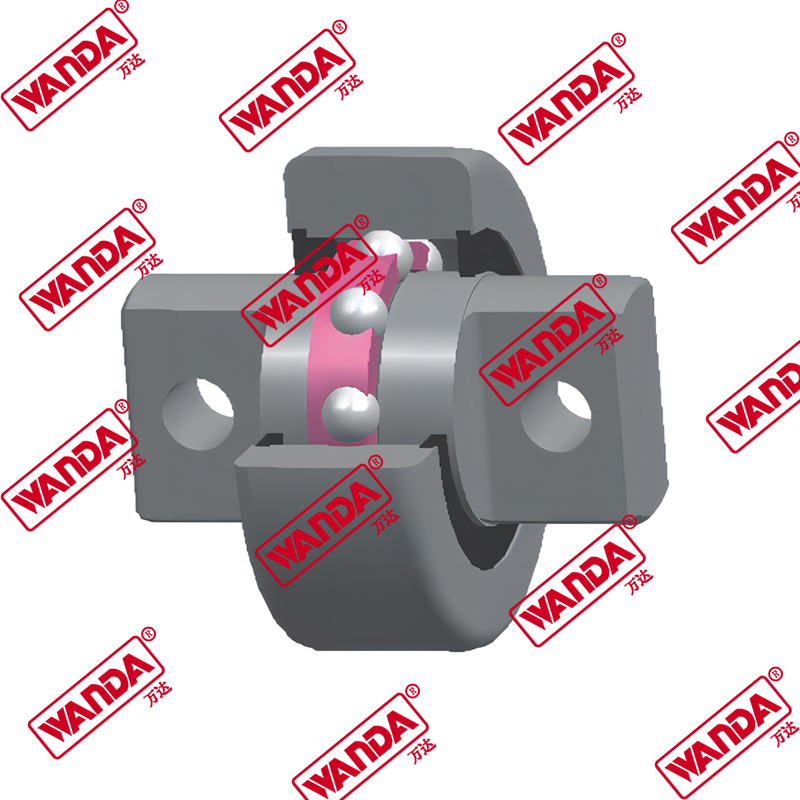

Side rollers are usually installed on both sides of the forklift, and they maintain a certain contact pressure with the ground. When the forklift turns, the side rollers immediately sense the tilting tendency of the vehicle body, and through the friction with the ground, they generate a reverse force, effectively offsetting the centrifugal force. This seemingly simple mechanical structure actually contains exquisite mechanical principles, which allows the forklift to maintain a stable body even when turning at high speed, greatly improving the driving safety and stability of the cargo.

Shock absorber on uneven roads

In addition to the stability challenge when turning, forklifts often encounter uneven roads during driving. The potholes and bumps on these roads will cause the vehicle body to bump, which not only affects the driver's comfort, but may also cause damage to the forklift itself and the cargo it carries. At this time, the side rollers once again play their unique role.

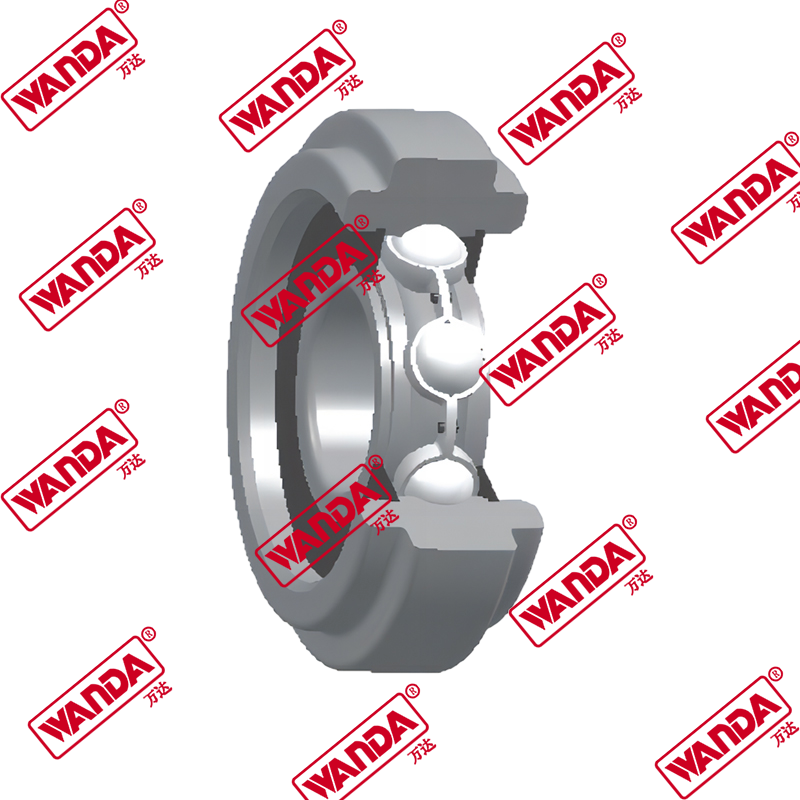

The side rollers have certain elasticity and shock absorption properties. When the forklift is driving on an uneven road, they can absorb the vibration of the road and reduce the bumps of the vehicle body. This shock absorption effect not only improves the driver's driving experience, but more importantly, it protects the safety of the forklift and cargo, and reduces the damage that may be caused by bumps. At the same time, the side roller can also adjust the posture of the vehicle body to a certain extent, ensuring that the forklift can maintain a stable driving state under complex road conditions.

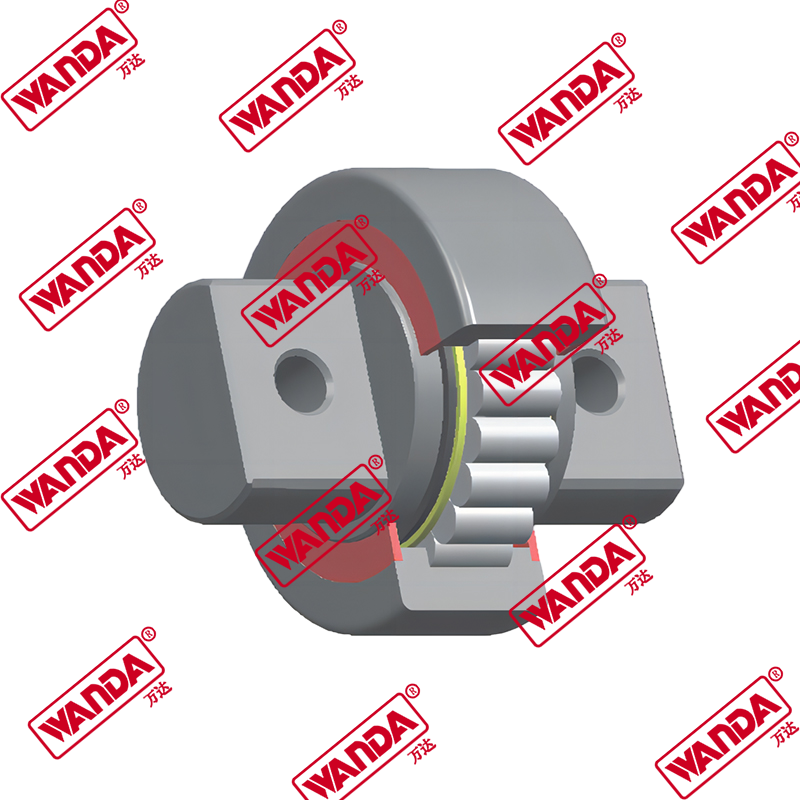

Design and maintenance of side rollers

The design of forklift side rollers is not done overnight. It needs to take into account many factors, such as the choice of materials, the rationality of the structure, wear resistance, and the contact pressure with the ground. High-quality side rollers are usually made of high-strength and wear-resistant materials to ensure that they can maintain good performance during long-term use. At the same time, reasonable structural design also enables the side rollers to evenly distribute force when under pressure to avoid damage caused by local overload.

Of course, the performance of the side rollers also requires regular maintenance and inspection to ensure. The driver should regularly check the wear of the side rollers and replace the severely worn side rollers in time to ensure that they always maintain good working conditions. In addition, for forklifts that often travel under harsh road conditions, the maintenance of the side rollers should be strengthened to extend their service life.