1. Basic composition of forklift slewing bearing

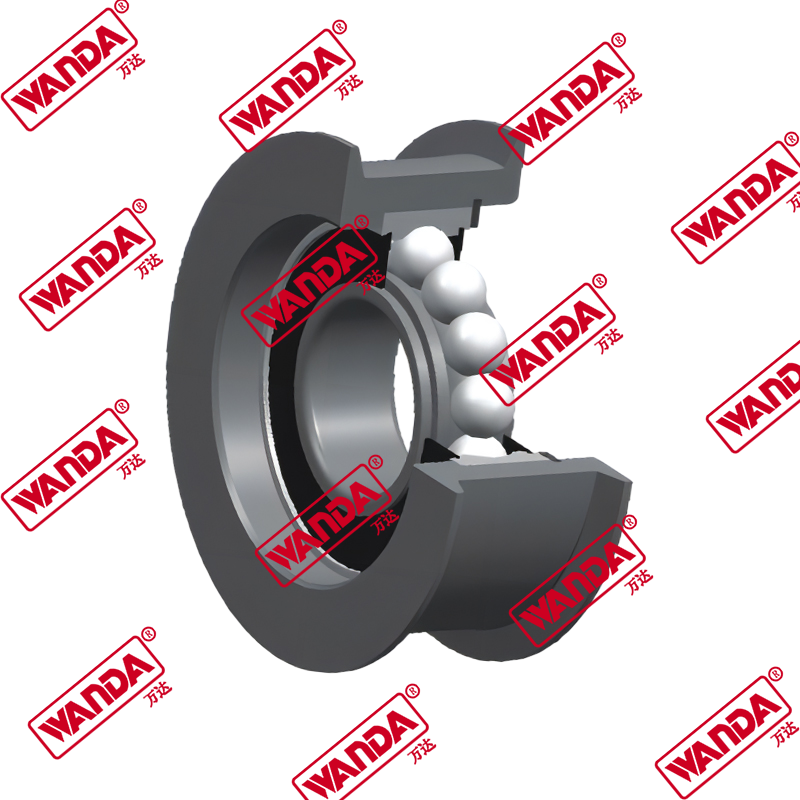

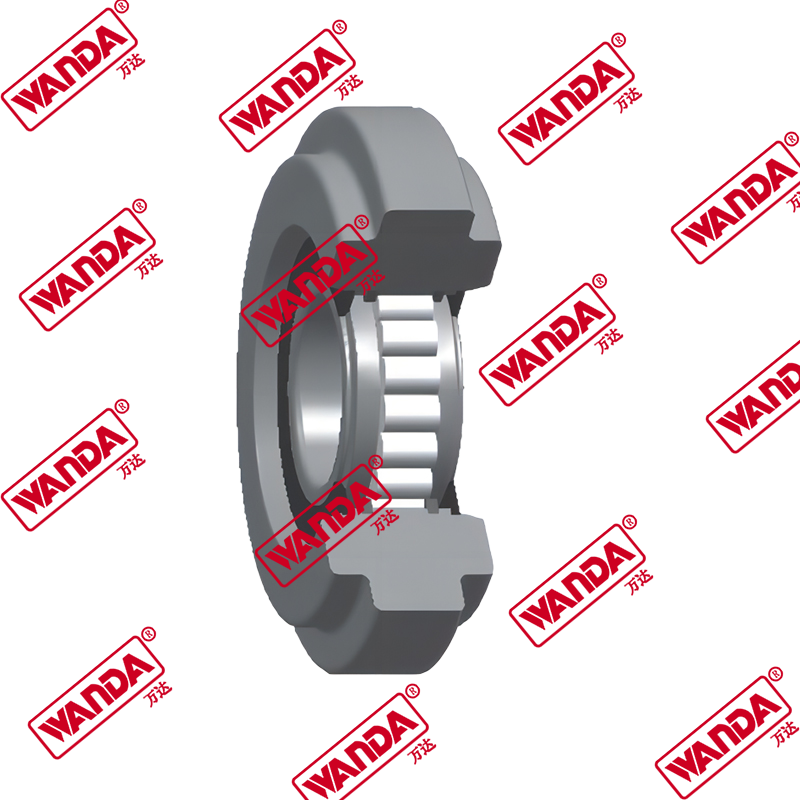

Forklift slewing bearing, as a key component connecting the forklift body and rotating parts (such as cab, fork frame), is usually composed of several core components such as inner and outer ring tracks, rolling elements, retainers and seals.

Inner and outer ring tracks: This is the basic framework of the slewing bearing. The inner ring is usually firmly fixed to the forklift body by bolts or welding, while the outer ring is connected to the part that needs to rotate (such as cab, fork frame). The material of the inner and outer rings is mostly high-strength alloy steel to ensure sufficient load-bearing capacity and wear resistance.

Rolling element: Located between the inner and outer rings, it is the key to realize the rotation function. Common rolling elements are spheres and rollers. Ball rolling bearings have a lower friction coefficient and better self-rotation performance, and are suitable for high-speed rotation occasions; while roller bearings have higher load-bearing capacity and anti-overturning ability, and are more suitable for heavy load and low-speed rotation applications. The selection of rolling elements should be determined according to the working environment and load requirements of the forklift.

Cage (ball cage): used to evenly distribute rolling elements to prevent them from squeezing or falling off each other during operation, while reducing direct contact between rolling elements and inner and outer rings and reducing wear. The design of the cage is directly related to the smooth operation and service life of the slewing bearing.

Seal: located on the periphery of the slewing bearing, it is used to prevent the intrusion of impurities such as dust and moisture, protect the internal rolling elements and lubricating grease, and ensure the sealing and durability of the slewing bearing.

2. Working principle and performance characteristics

The working principle of the forklift slewing bearing is based on the principle of rolling friction, that is, the relative rotation between the inner and outer rings is achieved by the rolling of the rolling elements. When the forklift operator turns the steering wheel, the steering mechanism drives the outer ring to rotate relative to the inner ring, and the rolling elements roll between the inner and outer rings, thereby realizing flexible steering of the forklift cab and the fork part.

This design not only significantly reduces friction resistance and improves steering efficiency, but also greatly reduces energy loss, making the forklift more energy-efficient and efficient in operation. In addition, the high load-bearing capacity and good anti-overturning performance of the slewing bearing ensure that the forklift can still perform steering operations stably and safely when carrying heavy objects.

3. Impact on forklift performance

The performance of the forklift slewing bearing directly affects the operational flexibility, stability and durability of the forklift. High-quality slewing bearings can provide a smooth and unobstructed rotation experience, reduce the sense of frustration during operation, and improve the driver's comfort and work efficiency. At the same time, good sealing performance and wear resistance ensure the long-term stable operation of the slewing bearing under harsh working conditions and extend the service life of the forklift.

On the contrary, if the slewing bearing is improperly designed or poorly maintained, it may cause serious wear of the rolling element and seal failure, which will affect the steering accuracy, stability and safety of the forklift. In severe cases, it may even cause forklift failure and affect production progress.