Combination bearings are a commonly used bearing assembly method in engineering applications. By rationally combining different types of bearings, they make full use of the characteristics of each bearing, thereby improving the overall load-bearing capacity. Different types of bearings can withstand loads in different directions, and by combining them, they can simultaneously withstand loads in multiple directions, thereby greatly improving the load-bearing capacity of the bearings.

Understanding the basic principles of Combination bearings is crucial to deepening your understanding of their advantages. Traditional bearings often can only withstand loads in a specific direction, and cannot simultaneously withstand loads in multiple directions. However, Combination bearings combine multiple one-way load-bearing bearings to form a single load-bearing system. In this way, Combination bearings can effectively withstand radial, axial, and oblique loads. This ability makes Combination bearings more suitable than traditional one-way load-bearing bearings for various complex load situations.

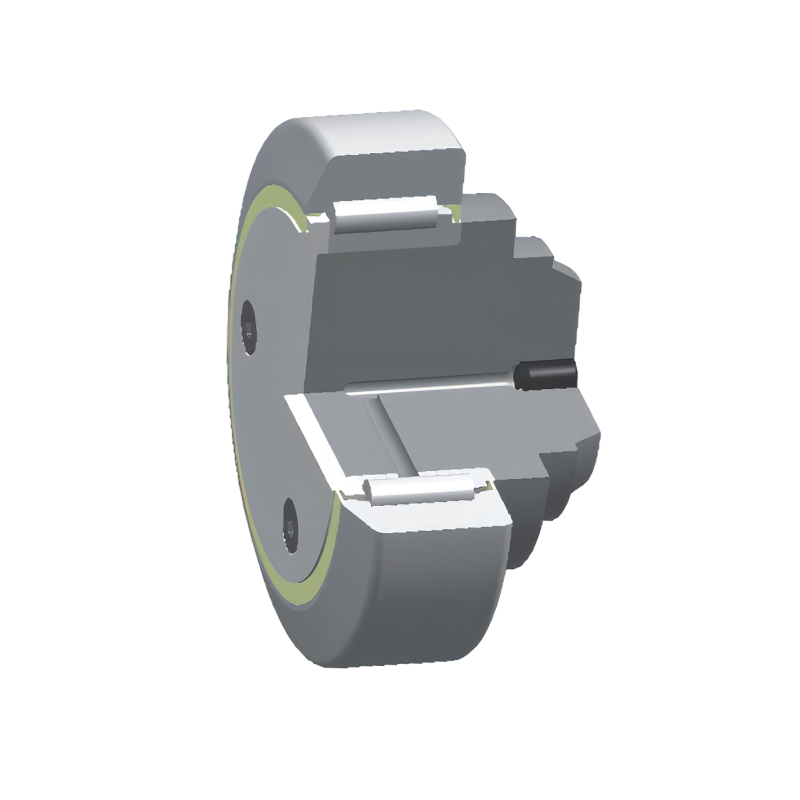

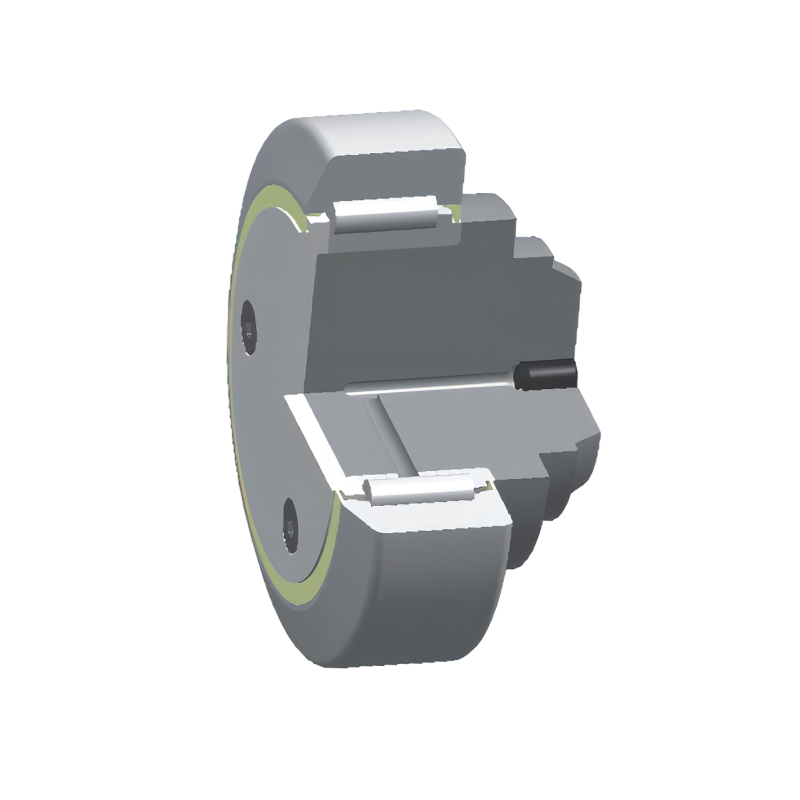

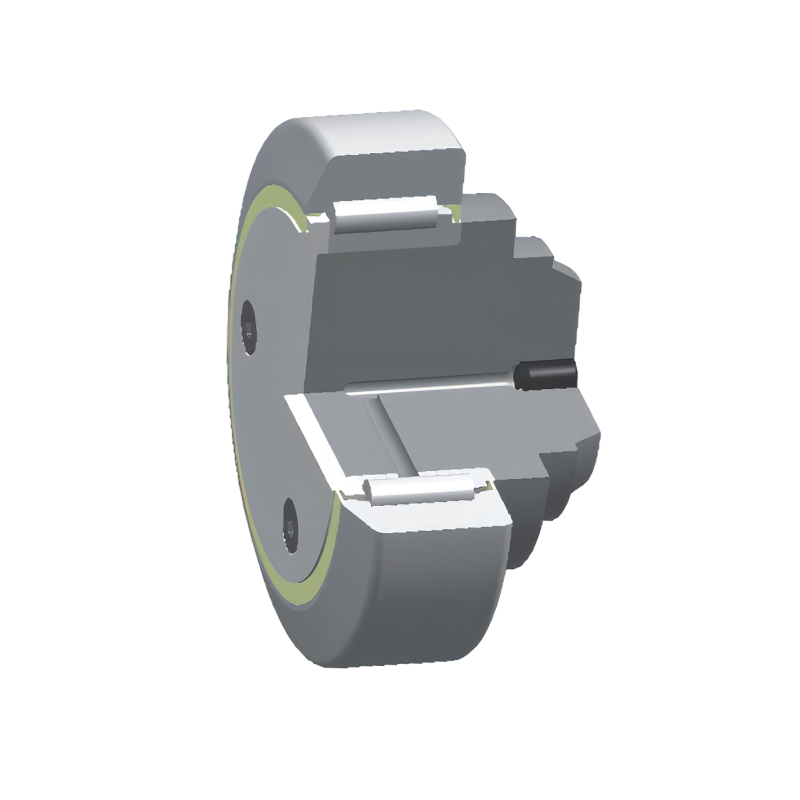

The design and selection of Combination bearings are also crucial. When designing Combination bearings, it is necessary to consider the characteristics of each bearing and their synergistic effects when combined. For example, a common combination of bearings is the combination of angular contact ball bearings and tapered roller bearings. Angular contact ball bearings can withstand large radial loads and some axial loads, while tapered roller bearings can withstand larger axial loads. By combining them, they can simultaneously withstand larger radial and axial loads, improving the overall load-bearing capacity of the bearing. At the same time, more bearing types can be selected according to the actual situation, such as cylindrical roller bearings, spherical roller bearings, etc., to meet the needs of different directional loads.

The application of Combination bearings is widespread. Due to their ability to withstand loads in more directions, Combination bearings are widely used in heavy-duty, high-speed, and high-precision engineering applications. For example, large-scale machine tools, engineering machinery, wind turbine generators, and ships all require complex load conditions to be withstood. By properly designing and selecting Combination bearings, the reliability and stability of the overall system can be significantly improved.

Combination bearings improve the overall load-bearing capacity by rationally combining different types of bearings and utilizing the characteristics of each bearing. It can simultaneously withstand loads in multiple directions, thereby greatly improving the load-bearing capacity of the bearing. The design and selection of combination bearings are very important, and it is necessary to consider the characteristics of different bearings and the synergistic effects of their combination. It has a wide range of applications, especially suitable for heavy-duty, high-speed, high-precision engineering applications. It is believed that with the continuous progress and innovation of technology, combination bearings will play an important role in more fields and provide more reliable and stable solutions for engineering applications.