In busy warehousing and logistics sites, forklifts are like tireless beasts, undertaking the important tasks of cargo transportation and stacking. Among the many "joints" of this giant beast, the forklift slewing bearing is undoubtedly the key to its flexible operation. It not only connects the fork and frame of the forklift, but is also the core component for the forklift to achieve all-round operation.

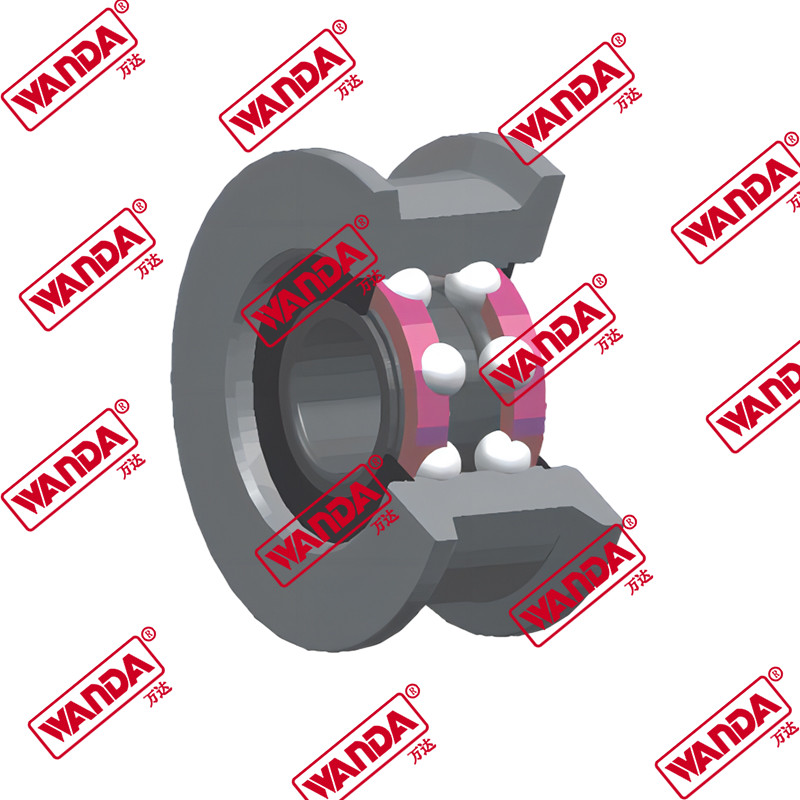

As a bridge connecting the fork and the frame, the forklift slewing bearing's primary task is to ensure a stable connection between the two. When a forklift transports goods, the forks bear tremendous pressure from the goods. This pressure needs to be effectively transmitted to the frame through the slewing bearing to ensure the overall stability of the forklift. In addition, the slewing bearing must withstand various moments and impact forces generated during the operation of the forklift, providing solid support for the forklift.

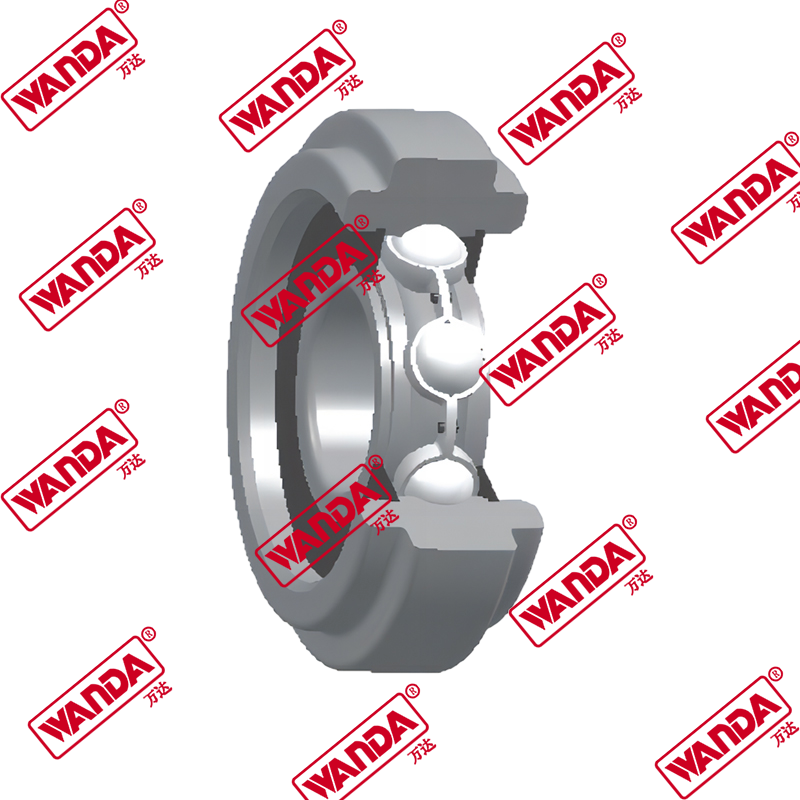

The reason why a forklift can flexibly shuttle in a small space, carry out transportation and stacking at various angles, is inseparable from the contribution of the slewing bearing. Through the relative rotation between the inner and outer rings, the slewing bearing allows the fork to easily rotate left and right to meet various complex operating requirements. This flexibility not only improves the working efficiency of the forklift, but also greatly reduces the labor intensity of the operator.

In the warehousing and logistics industry, time is money. The efficient operation of forklifts is crucial to improving the efficiency of the entire warehousing and logistics system. The excellent performance of the slewing bearing is the guarantee for the efficient operation of the forklift. It ensures that the forklift can complete various actions quickly and accurately when moving goods, thus improving work efficiency. At the same time, because the slewing bearing has good stability and load-bearing capacity, it can also improve the safety of forklift operations to a certain extent and reduce the probability of accidents.

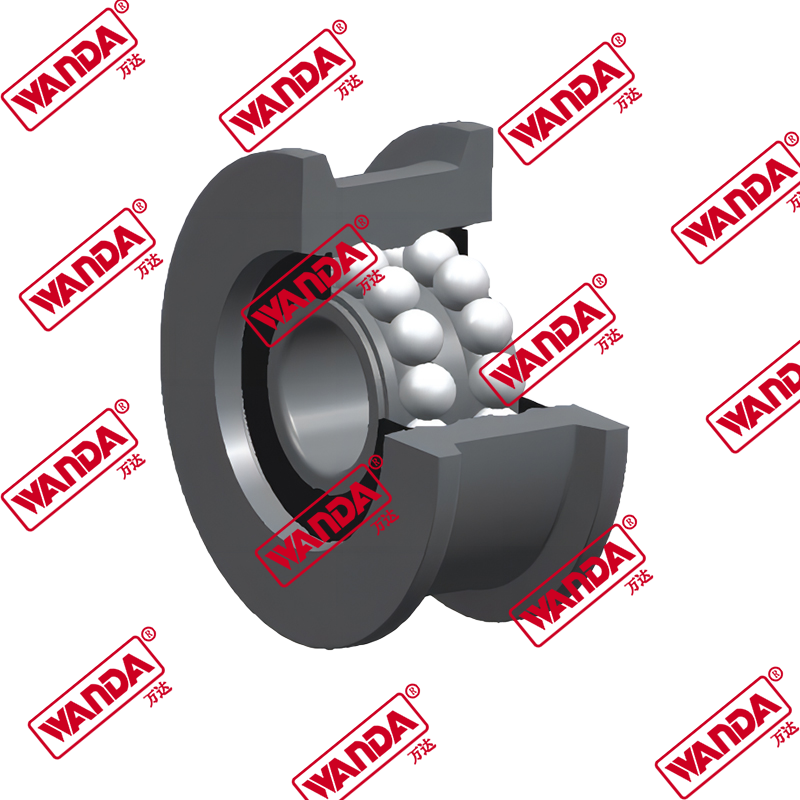

The performance and quality of the slewing bearing directly affect the overall performance and life of the forklift. If the slewing bearing is of poor quality or improperly maintained, it will cause increased wear and decreased accuracy, which will affect the operational flexibility and stability of the forklift. This will not only reduce the working efficiency of the forklift, but may also cause safety accidents. Therefore, choosing a slewing bearing with excellent performance and reliable quality is of great significance to ensure the normal operation of the forklift and extend its service life.

In order to ensure the good performance of the forklift slewing bearing and extend its service life, regular maintenance is essential. This includes regular cleaning, checking lubrication, tightening loose fasteners, and replacing severely worn parts. Through these measures, problems with the slewing bearing can be discovered and solved in time to ensure that it is always in good working condition.

The forklift slewing bearing is one of the important components of the forklift, and its importance is self-evident. It is not only a bridge connecting the fork and the frame, but also the key to achieving flexible operation of the forklift and improving work efficiency and safety. When purchasing a forklift, we need to pay full attention to the performance and quality of the slewing bearing; during use, we also need to pay attention to its maintenance work to ensure the normal operation of the forklift and extend its service life.