In the rapidly evolving logistics and material handling sector, advancements in equipment design are constantly pushing the boundaries of performance and reliability. One such breakthrough innovation that has captured the attention of industry professionals worldwide is the introduction of the CRAxx-xP Axial Bearing, designed with an adjustable bracket system, revolutionizing the efficiency and durability of forklift masts.

The Rise of Adjustable Axial Bearings

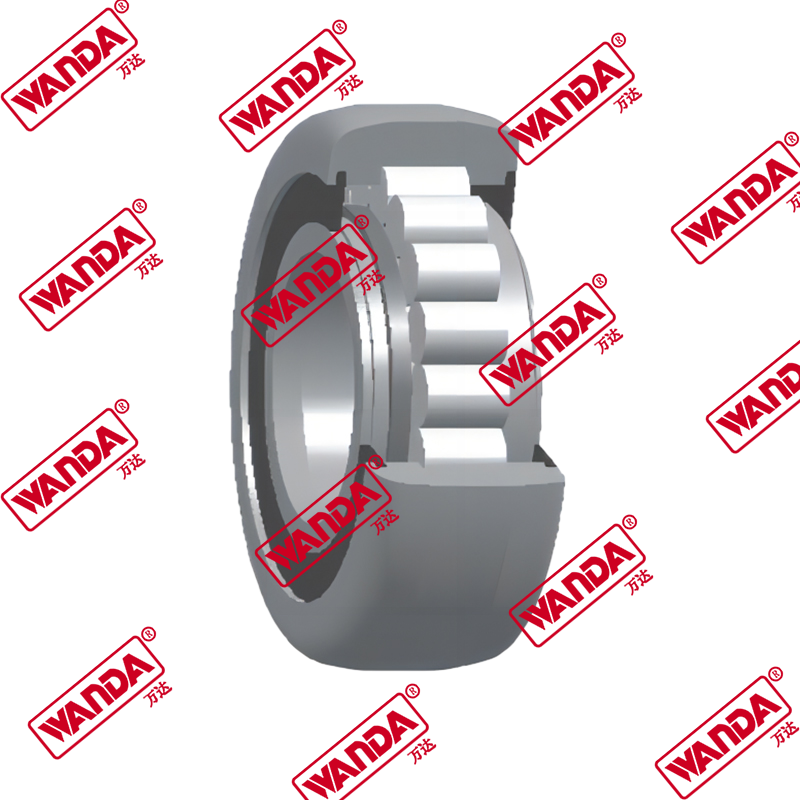

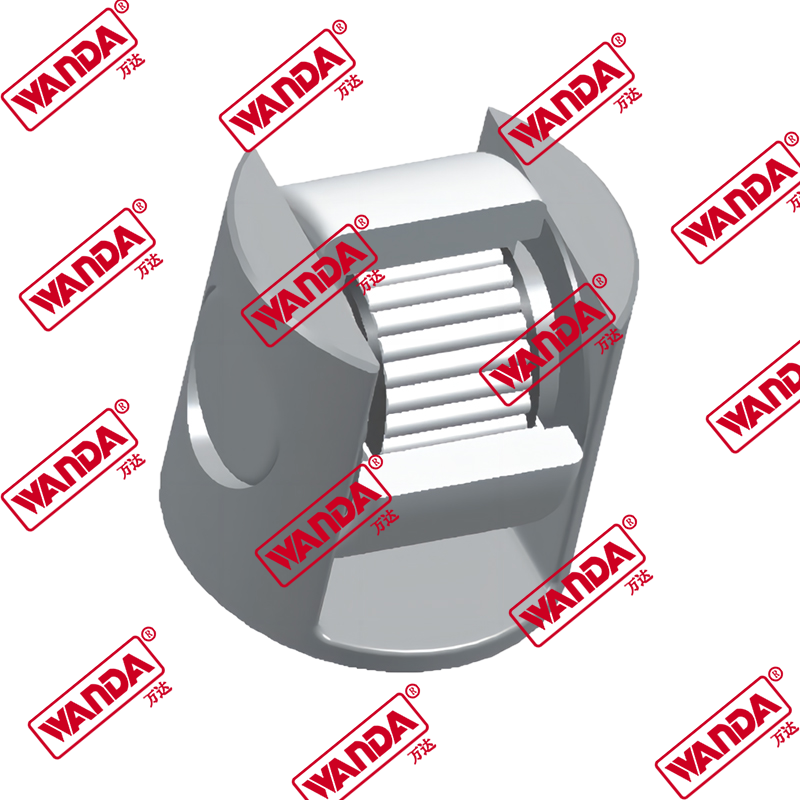

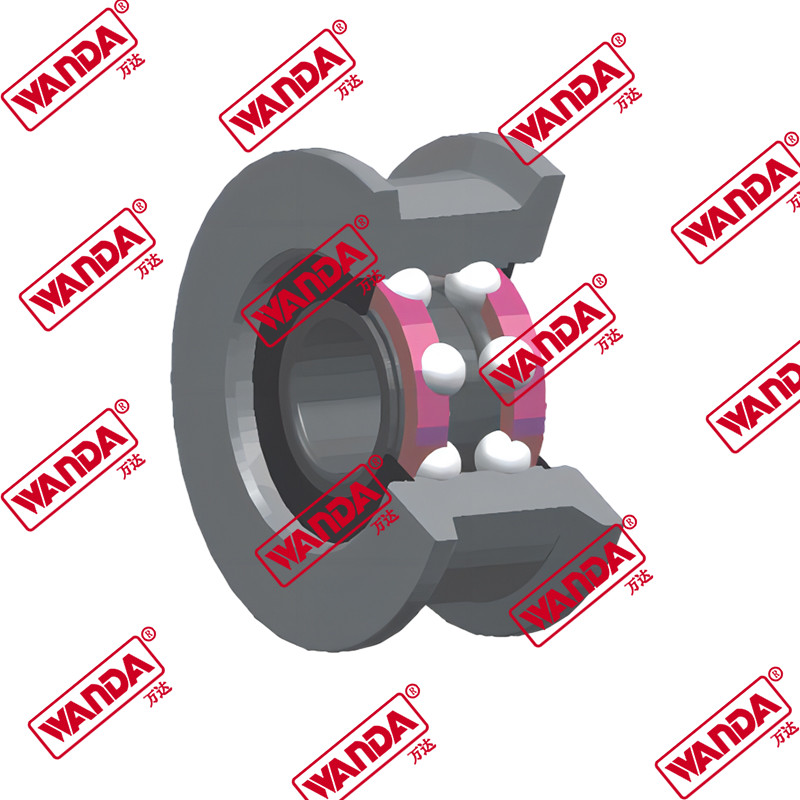

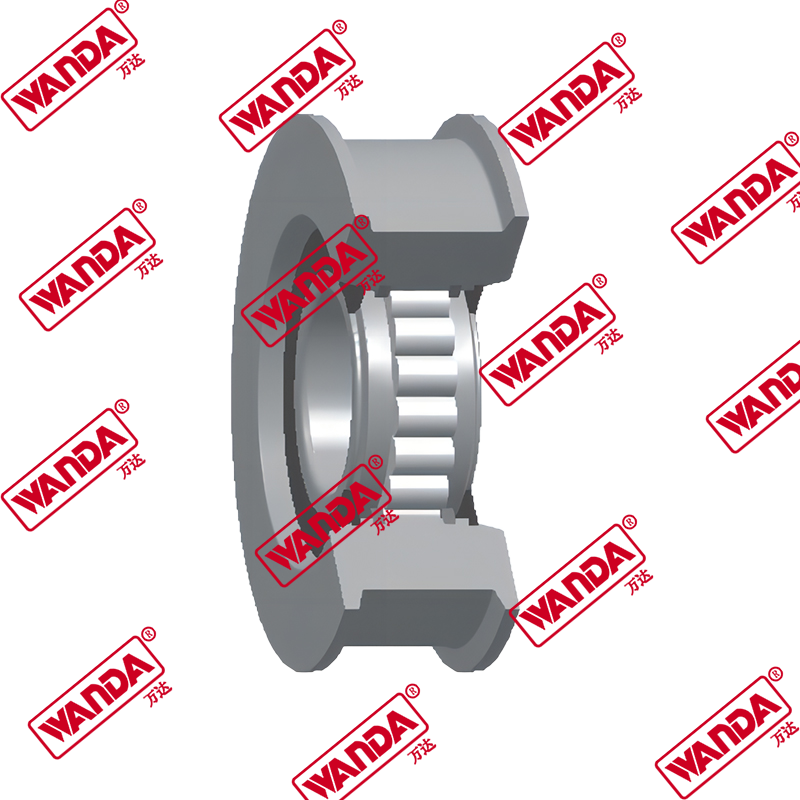

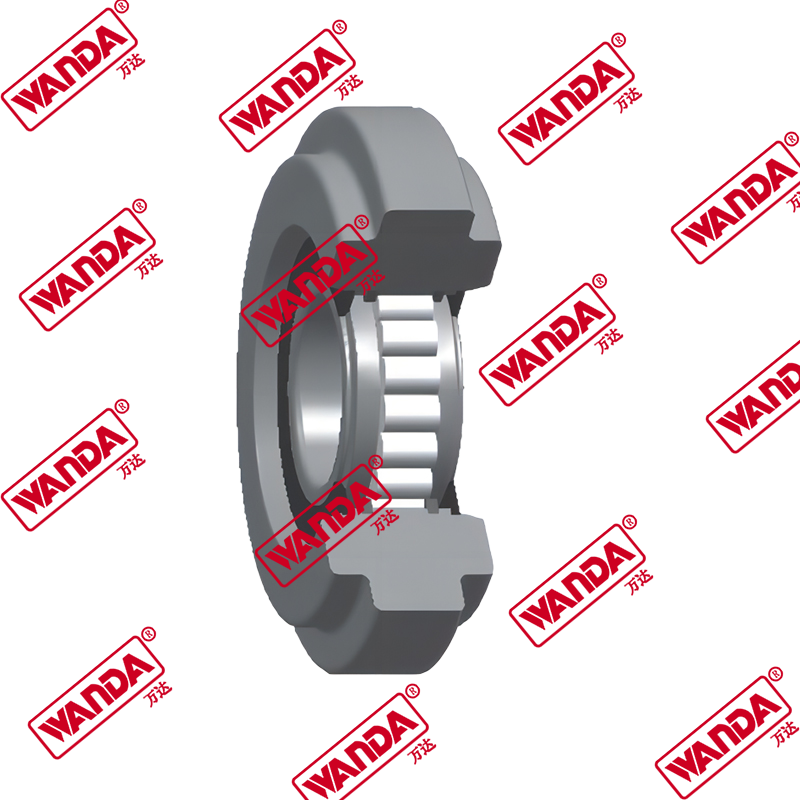

Traditionally, forklift mast bearings have faced challenges in maintaining optimal alignment and tolerance during prolonged usage, leading to premature wear and tear. However, the CRAxx-xP Axial Bearing, with its unique adjustable bracket, addresses these issues head-on. The innovative design allows for seamless integration and fine-tuning, ensuring a perfect fit between the bearing and the shaft, minimizing friction and maximizing operational efficiency.

Revolutionizing Installation Methods

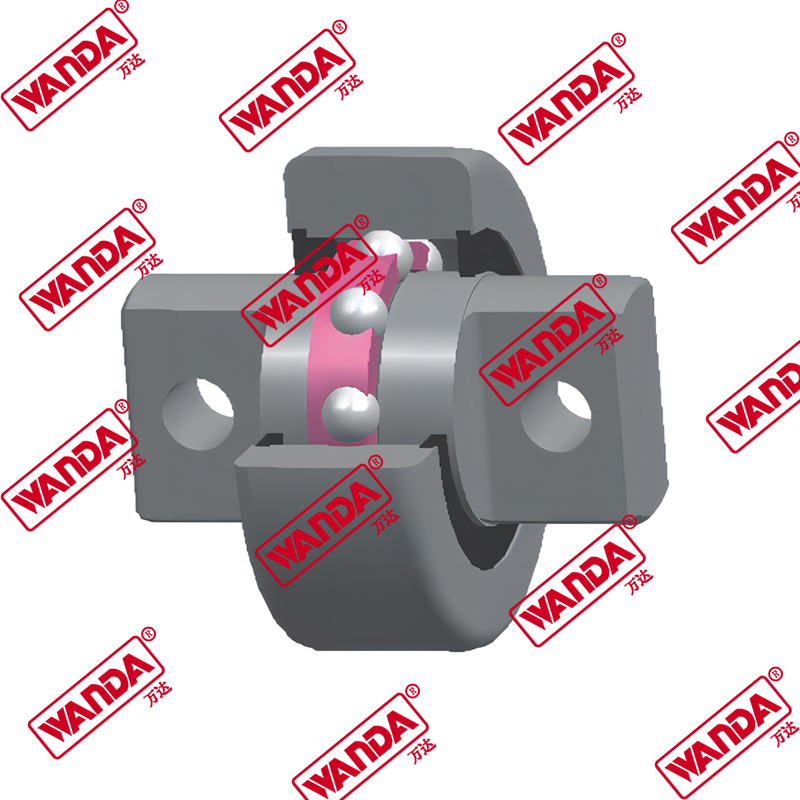

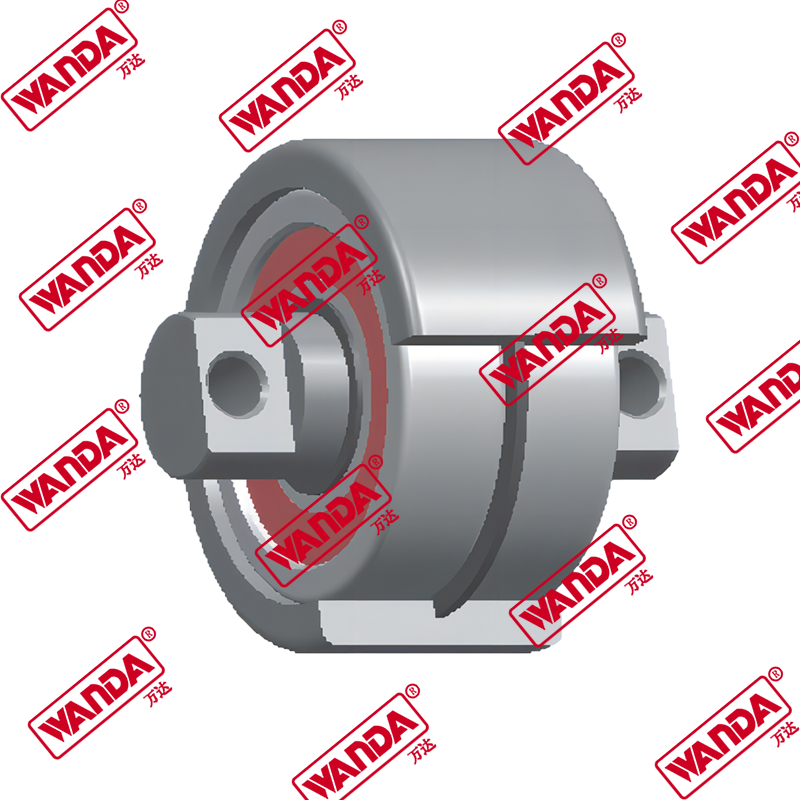

Gone are the days of cumbersome installation processes and complex maintenance requirements. The CRAxx-xP Axial Bearing offers a simplified installation method, utilizing a fixed retaining ring matched specifically to the bearing, ensuring a smooth and transitional fit. This eliminates the need for excessive adjustments or replacements, saving time and reducing downtime significantly. Moreover, the use of half-hole bearing screw fixation and shaft fit gland fixation methods offers further flexibility and adaptability to varying forklift designs.

Pushing the Boundaries of Testing Standards

Ensuring the reliability and longevity of forklift bearings is paramount to maintaining operational safety and reducing maintenance costs. The CRAxx-xP Axial Bearing undergoes rigorous testing protocols, including both static and dynamic pressure tests. The static pressure test, conducted using a state-of-the-art testing machine, subjects the bearing to intense loads, measuring its bearing capacity until the point of failure. Meanwhile, the dynamic pressure test simulates real-world operating conditions, where the outer wheel is linearly pressurized and loaded to preset loads, simulating the stresses endured during daily operations.

Aligning with Modern Trends and Challenges

In today's fast-paced business environment, companies are under immense pressure to increase productivity while minimizing costs. The CRAxx-xP Axial Bearing, with its adjustable bracket and advanced testing protocols, is the perfect solution for logistics and material handling businesses looking to optimize their forklift fleets. Its durability and reliability reduce maintenance requirements, lower operational costs, and improve overall efficiency, aligning perfectly with the demands of modern industries.

The CRAxx-xP Axial Bearing with its adjustable bracket system represents a significant leap forward in forklift technology. Its innovative design, simplified installation methods, and rigorous testing protocols have set new standards for the industry, ensuring maximum efficiency, durability, and safety. As businesses continue to embrace advancements in logistics and material handling, the CRAxx-xP Axial Bearing stands as a testament to the relentless pursuit of excellence and the drive to stay ahead of the curve.