In the modern logistics system, forklifts are indispensable material handling equipment, and their stability and efficiency directly determine the operating efficiency of the entire logistics system. In a forklift, the pulley bearing is one of its core components, and the stability of its performance is directly related to the overall performance and operating efficiency of the forklift.

The forklift sheave bearing is the core component of the forklift pulley. It carries the main load of the forklift during operation and operation, and plays a supporting and guiding role. The smooth operation of pulley bearings can not only reduce friction and energy consumption, but also improve the working efficiency of forklifts. High-quality pulley bearings can also effectively reduce noise and vibration during forklift operation and improve driver comfort. Therefore, selecting and maintaining high-quality forklift pulley bearings is of great significance to ensure the normal operation of forklifts and improve the efficiency of the logistics system.

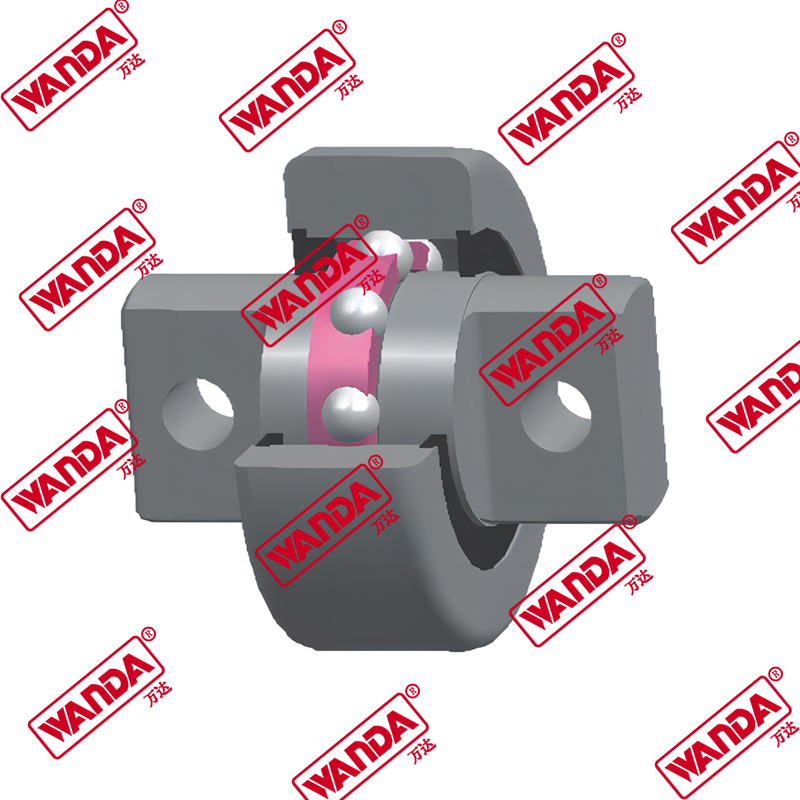

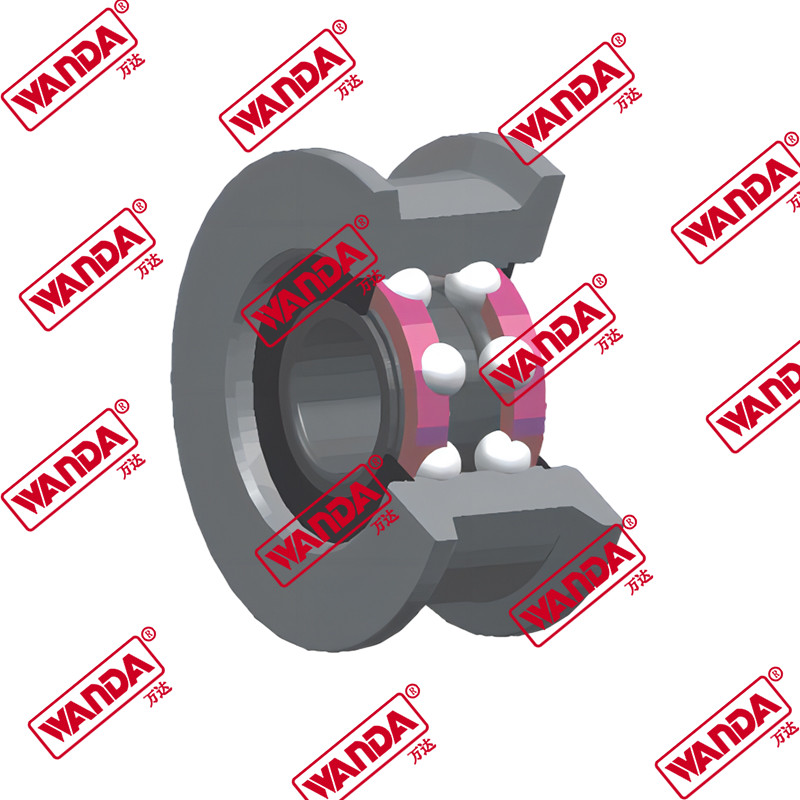

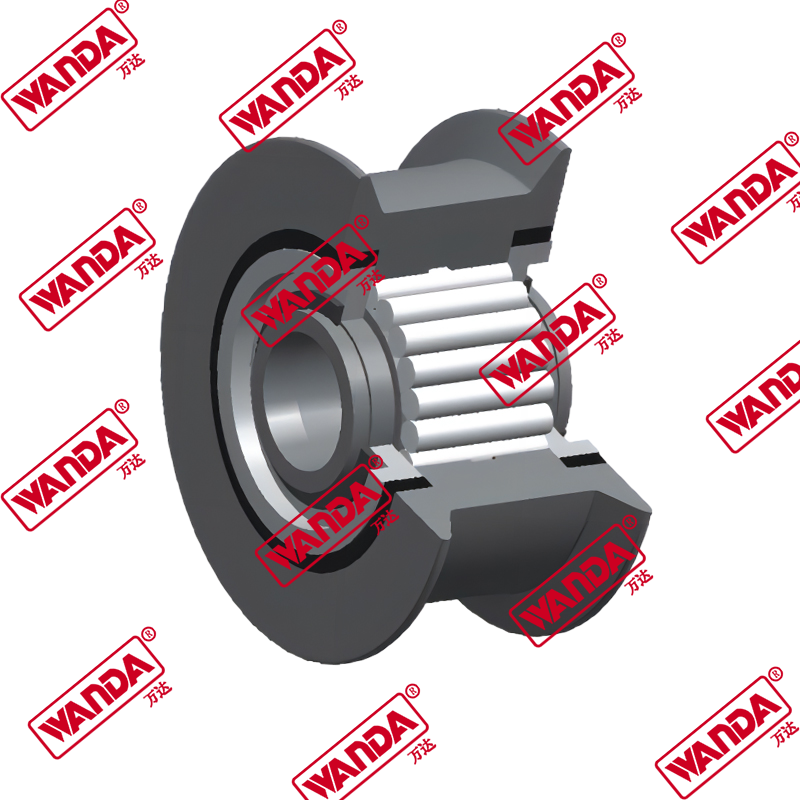

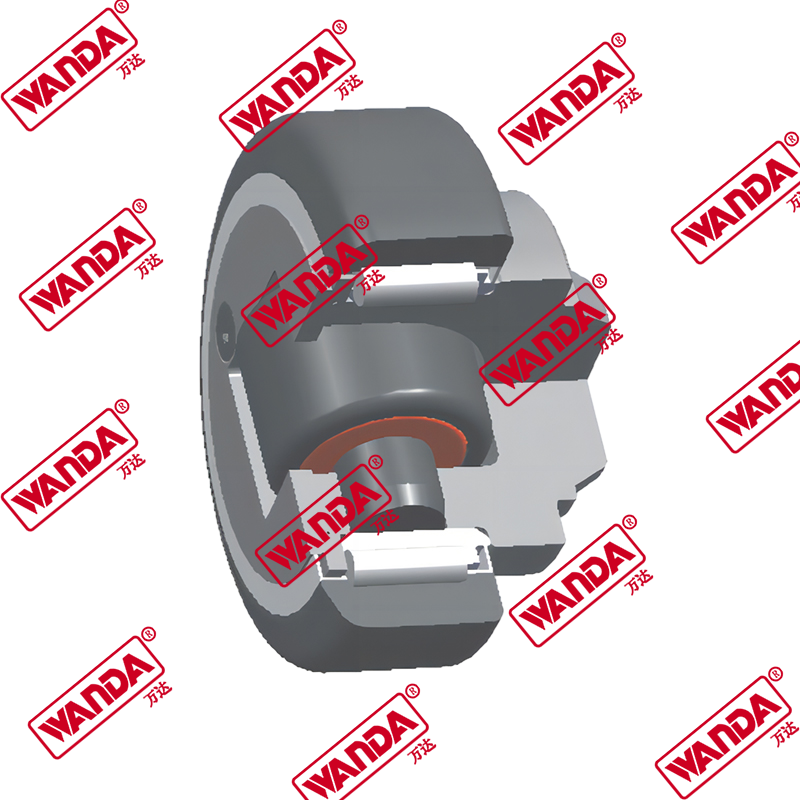

Forklift pulley bearings are mainly composed of four parts: wheel barrel, wheel axle, support plate and bearing. The wheel drum is a wheel rim made of cast steel or cast iron, which mainly bears the weight of the cargo; the wheel axle is the component that connects the wheel drum to the support plate and bears the rotational force of the wheel drum; the support plate is used to fix the bearing and support The plate of the wheel axle; the bearing is the core component that rotates the wheel barrel and axle.

During the operation of the forklift, when torque is required to lift the goods, the forklift's motor will generate thrust, which is transmitted to the hydraulic system, which controls the movement of the fork arm. At this time, the forks on the fork arms fork the goods and lift them. Due to the heavy cargo, pulleys are needed to reduce the load on the fork arms and make it easier to move the cargo. When the goods pass through the pulley, the drum of the pulley converts the weight of the goods into torque, which is transmitted to the bearing through the axle, causing the entire pulley to start rotating. During the rotation process, the wheel axle will be subject to the rotation force of the wheel drum, but the bearing can remain stable under the action of the support plate until the cargo is lifted.

When selecting a model, factors such as the working environment, load, speed, accuracy level, and applicable environment of the forklift need to be considered. The load index needs to meet the requirements of the actual working situation, the speed index needs to meet the requirements of the actual situation, and the accuracy level requirements are related to the accuracy requirements of the forklift. In addition, environmental factors such as temperature, humidity, dust, etc. where the forklift is used need to be considered.

During the installation process, attention needs to be paid to keeping the bearing clean to prevent dust, debris, etc. from entering the inside of the bearing. Lubrication is an important guarantee for the normal operation of forklift pulley bearings. It should be lubricated regularly to reduce friction and wear and extend the service life of the bearings. When adding lubricant, you should choose a suitable lubricant, such as lubricating oil or grease, and apply an appropriate amount between the rolling elements and the inner and outer rings of the bearing to ensure that the lubricant is evenly distributed.

Maintenance is an important measure to maintain good performance and extend the service life of forklift pulley bearings. In daily use, bearings should be inspected regularly, including their appearance, operating status and lubrication conditions. If the bearing is found to have abnormal sound, heat, wear, etc., it should be dealt with in time. The bearings should also be cleaned and lubricated regularly to ensure the cleanliness and lubrication performance of the bearings.