1. Classification and characteristics of steel material

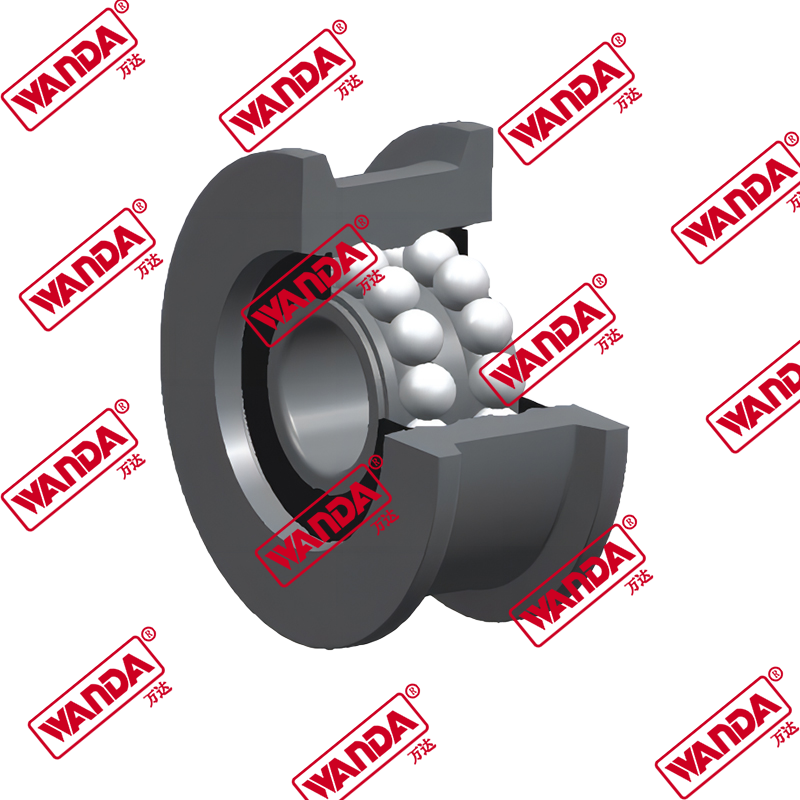

Steel, as an alloy material, is mainly composed of iron and a small amount of carbon. Other elements (such as chromium, molybdenum, manganese, etc.) may be added to improve its performance. In the manufacture of Forklift Chain Sheave, commonly used steels include carbon steel, alloy steel and stainless steel. Each type of steel has different characteristics, so the performance of forklift sprockets is also different.

Carbon steel (ordinary steel): Carbon steel is a metal material composed of iron and carbon, and the carbon content is generally between 0.12% and 2%. It has relatively low hardness and strength, but good processing performance and low cost. Carbon steel is usually used for forklift sprockets with lower loads or low corrosion resistance requirements.

Alloy steel: Alloy steel is a steel containing other alloy elements (such as manganese, chromium, nickel, molybdenum, etc.) in addition to carbon, which has higher hardness, strength, wear resistance and corrosion resistance. Commonly used for forklift sprockets in environments that bear greater pressure or require high temperature resistance and wear resistance.

Stainless steel: Stainless steel is an alloy steel containing at least 10.5% chromium, which has extremely strong oxidation resistance and corrosion resistance. It is not easy to rust and is suitable for wet and corrosive environments, but due to its high cost, it is usually only used in specific application scenarios, such as forklift applications in food processing or chemical industries.

2. The impact of steel on the performance of forklift sprockets

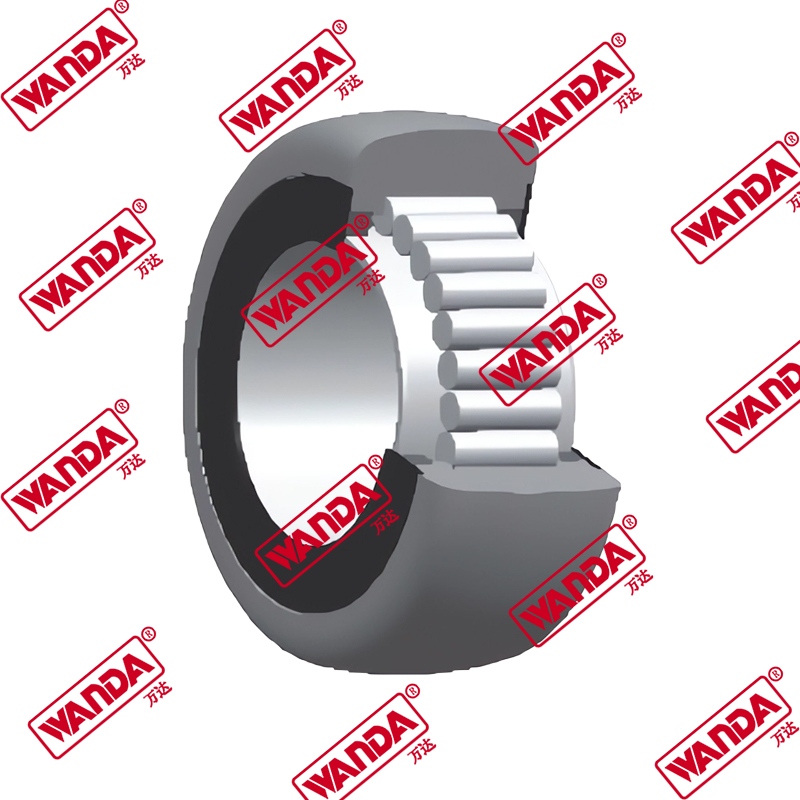

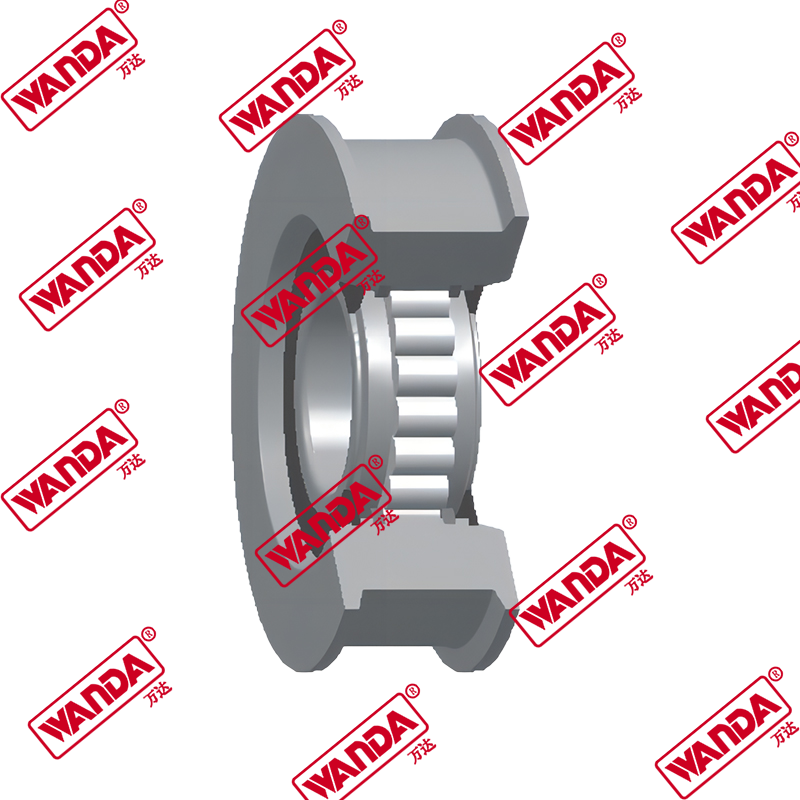

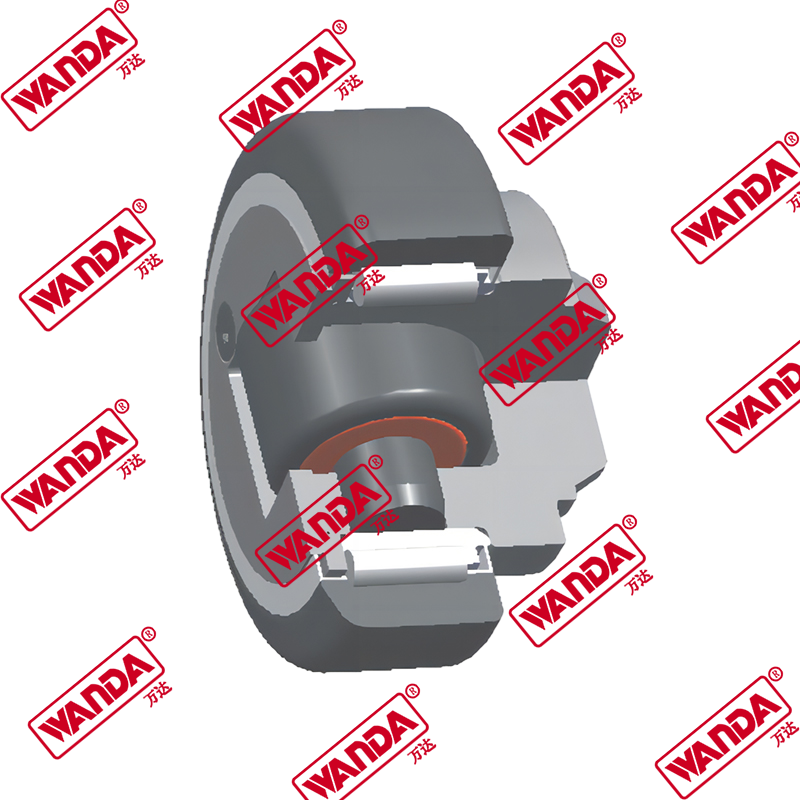

Forklift sprockets are mainly used to drive Forklift Chain Sheave, transmit power and drive cargo lifting. The performance of the sprocket has an important impact on the overall work efficiency, safety and service life of the forklift. As the main material, steel has a particularly significant impact on the forklift sprocket in the following aspects:

1. Strength and load-bearing capacity

The strength of steel determines the load that the forklift sprocket can withstand. Alloy steel and high carbon steel can withstand greater loads and pressures due to their high strength and strong wear resistance, which is crucial for forklifts operating under heavy loads. During the use of forklifts, the sprockets not only need to withstand the tension from the chain, but also need to withstand various impacts and friction during forklift operation. If low-strength steel (such as ordinary carbon steel) is used, the sprockets may be deformed, broken or excessively worn during long-term use, thus affecting the operating efficiency of the forklift.

For example, when using sprockets made of carbon steel materials, the sprockets may undergo plastic deformation or early fatigue cracks during high-load operations of forklifts, especially in environments where goods are frequently lifted and lowered. In contrast, sprockets made of alloy steel materials have stronger compressive resistance, can withstand higher workloads, and extend their service life.

2. Wear resistance

Forklift Chain Sheave will produce continuous friction with the chain during long-term operation. The wear resistance of steel determines whether the sprocket is prone to wear during friction. The faster the wear rate, the shorter the life of the sprocket. Because alloy steel materials contain a variety of alloy elements, they can effectively improve the hardness and wear resistance of the sprocket surface, thereby reducing the loss caused by friction.

If the wear resistance of the sprocket is poor, the wear caused by friction will make the sprocket tooth shape blunt, affecting the meshing effect of the chain, and then causing the chain to slip or work unstably. Alloy steel with good wear resistance can effectively reduce this situation and ensure that the forklift can still maintain a high working stability under long-term high-load work.

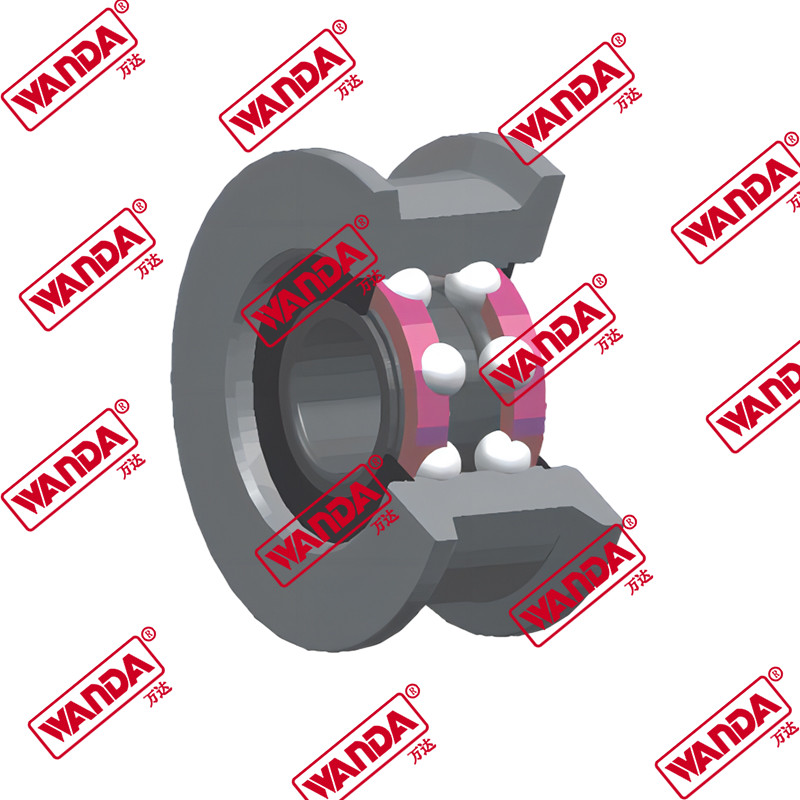

3. Corrosion resistance

Forklift Chain Sheave usually works outdoors or in industrial environments, and is prone to corrosion problems due to moisture, chemicals, oil pollution, etc. Especially in special industries such as food processing and chemical transportation, forklift sprockets need to resist a certain degree of corrosion. If stainless steel materials are used, the sprocket will have extremely strong oxidation resistance and corrosion resistance, and can work stably for a long time in a humid or corrosive gas and liquid environment.

For ordinary carbon steel sprockets, if effective anti-corrosion treatment is not performed, such as coating protection or regular cleaning, the surface of the sprocket may rust, reducing its service life and work efficiency. Alloy steel materials have good corrosion resistance, but compared with stainless steel, they may not perform as well as stainless steel in some extreme corrosive environme

nts.

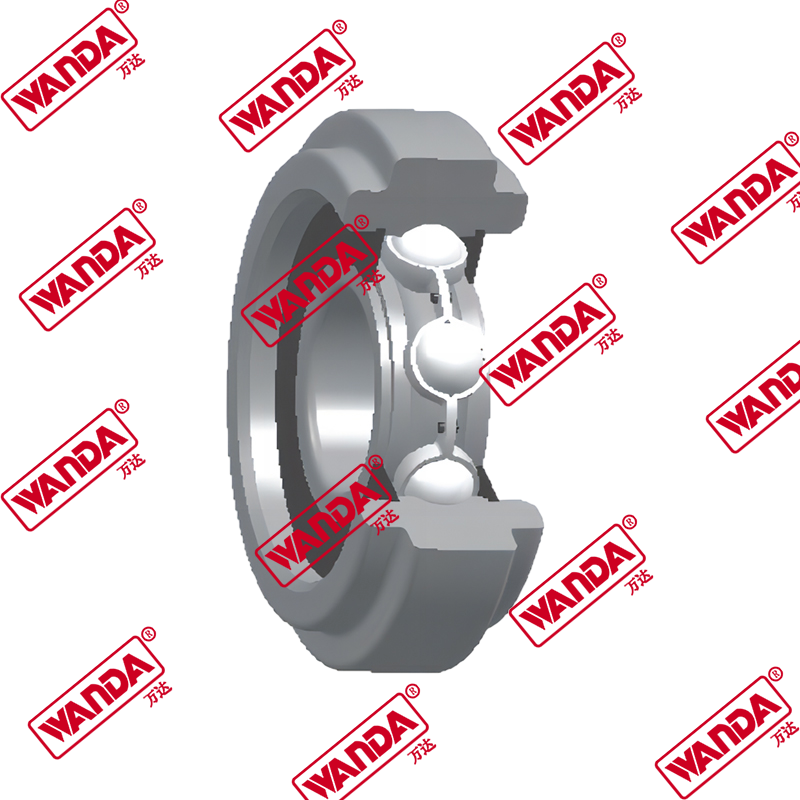

4. Heat treatment and hardness

Through heat treatment, steel can achieve higher hardness and stronger wear resistance. For example, the surface hardness of alloy steel sprockets treated by quenching and tempering process can be greatly improved, making it more suitable for high-intensity and high-frequency working environment. Steel with higher hardness can resist external impact and friction, prevent scratches, pits and other damage on the sprocket surface, and maintain good tooth shape and contact surface.

For forklift sprockets that need to work in high temperature environments, such as high-temperature warehouses or furnace transportation, it is particularly important to use heat-treated steel. Appropriate hardness can ensure that the sprocket still maintains good mechanical properties at high temperatures and avoid material softening and deformation caused by high temperature.

5. Processing performance and cost

The processing performance of steel also directly affects the production efficiency and cost of Forklift Chain Sheave. Ordinary carbon steel has good processability, is suitable for precision processing, and has low cost. It is suitable for forklift sprockets that do not require particularly high performance. However, the processing of alloy steel is relatively complex and may require higher process requirements, but its advantages in load-bearing capacity, wear resistance, corrosion resistance, etc. can provide guarantees for long-term and efficient operation, and are especially suitable for forklift application scenarios with higher requirements.