In the high-stakes environment of material handling, the structural integrity of a forklift mast is dictated by the prec...

READ MORE

Stock code: 920002

Stock code: 920002

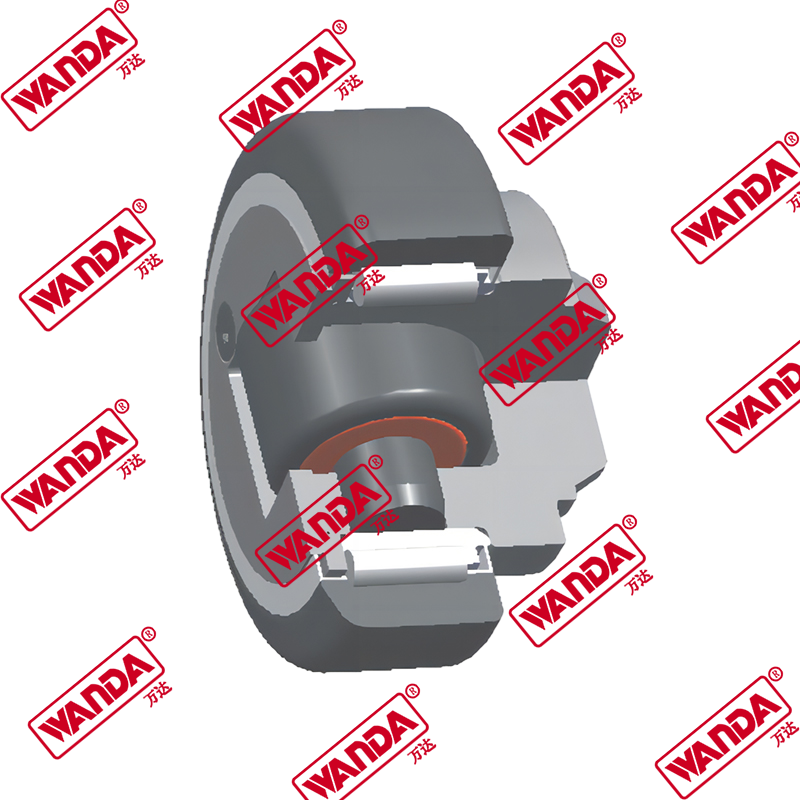

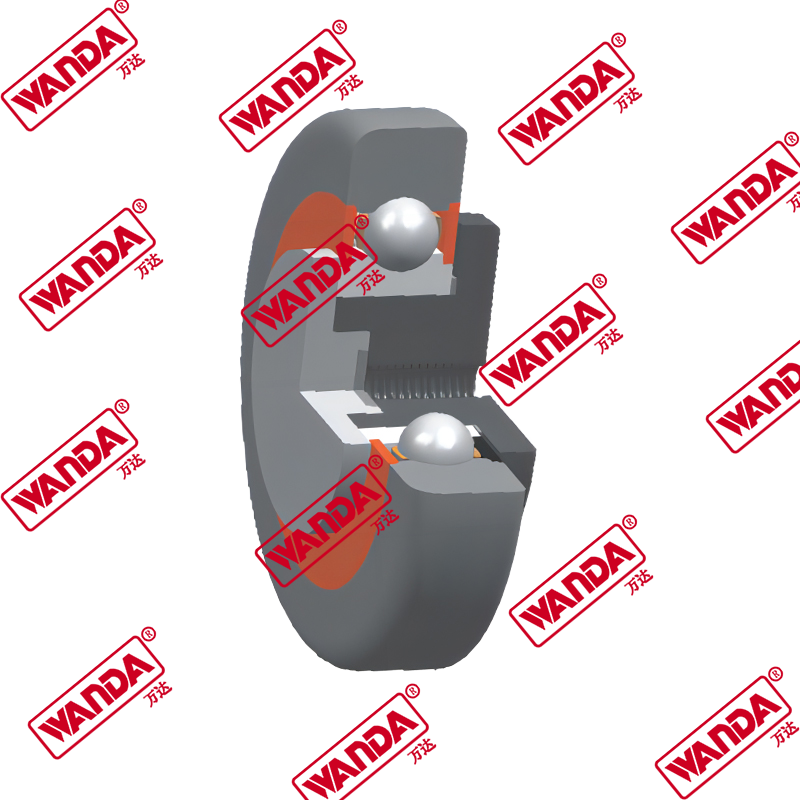

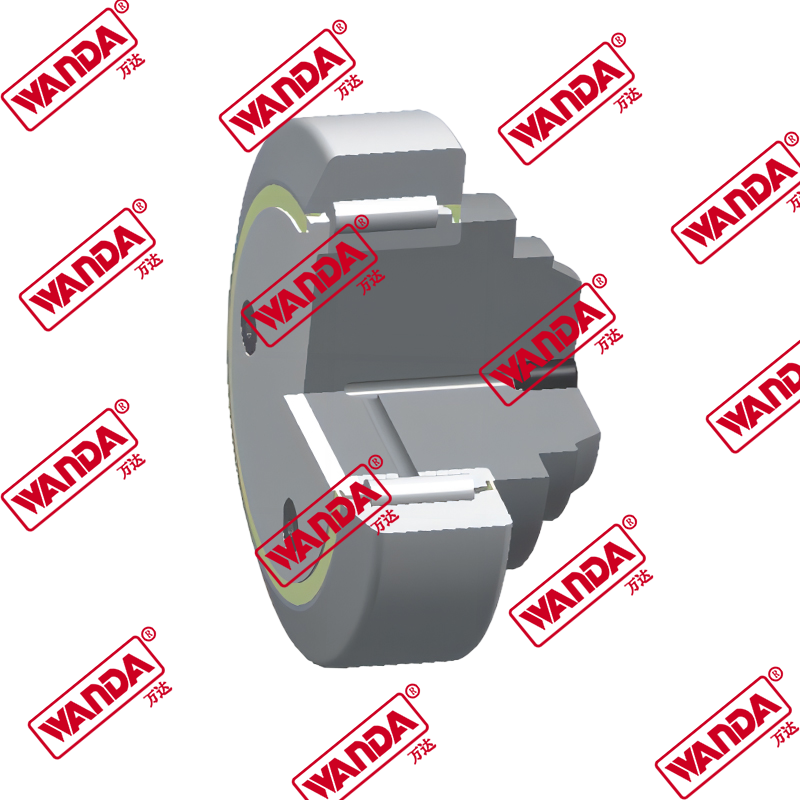

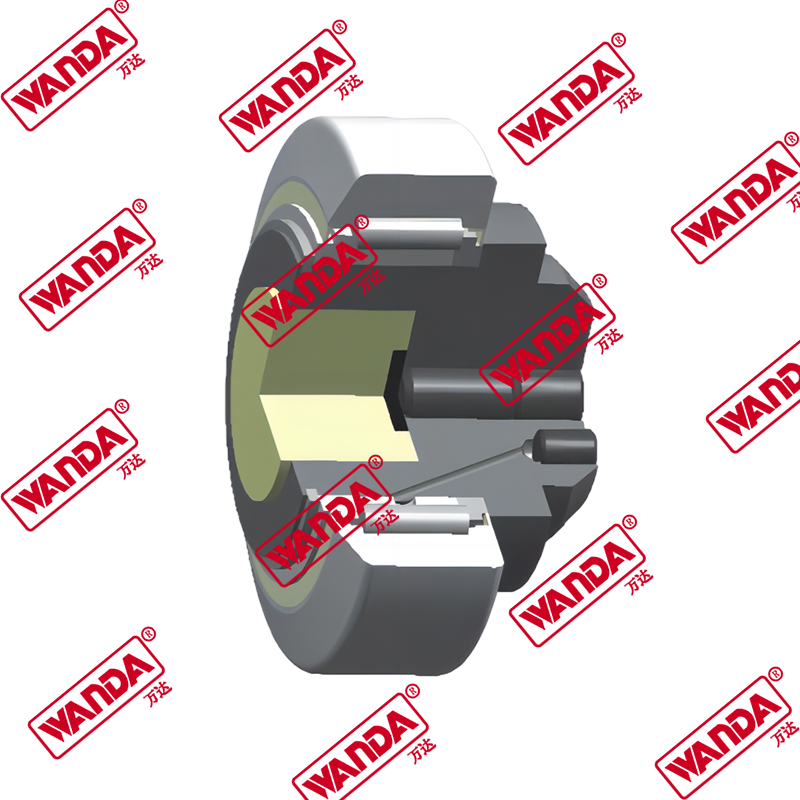

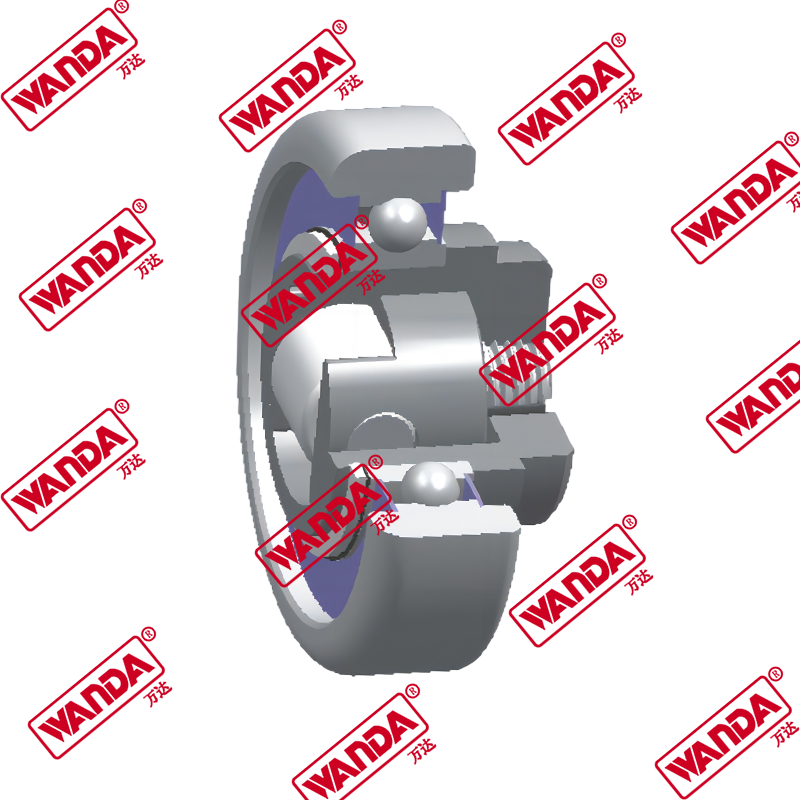

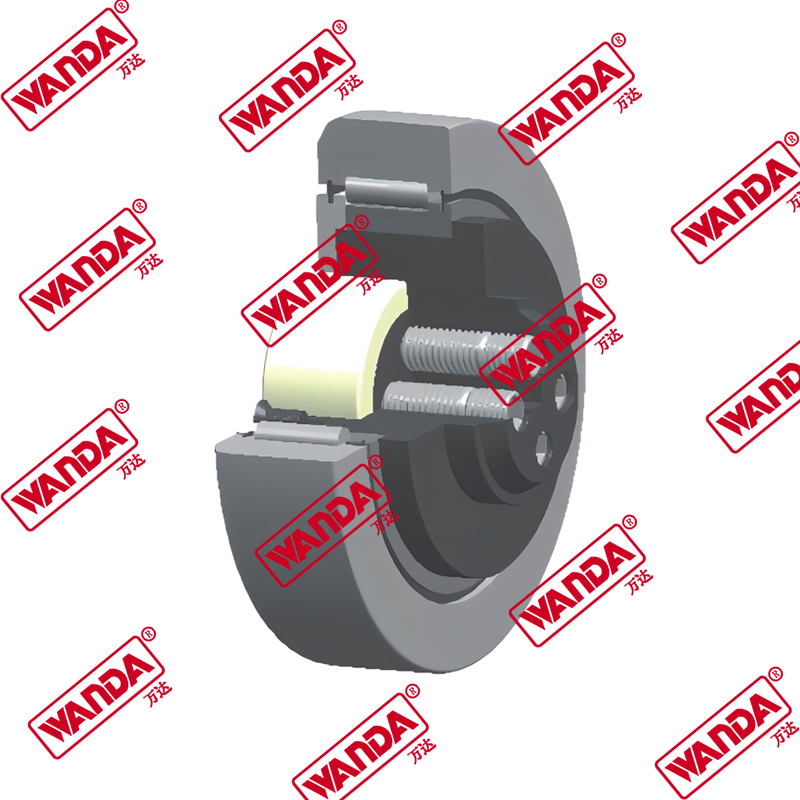

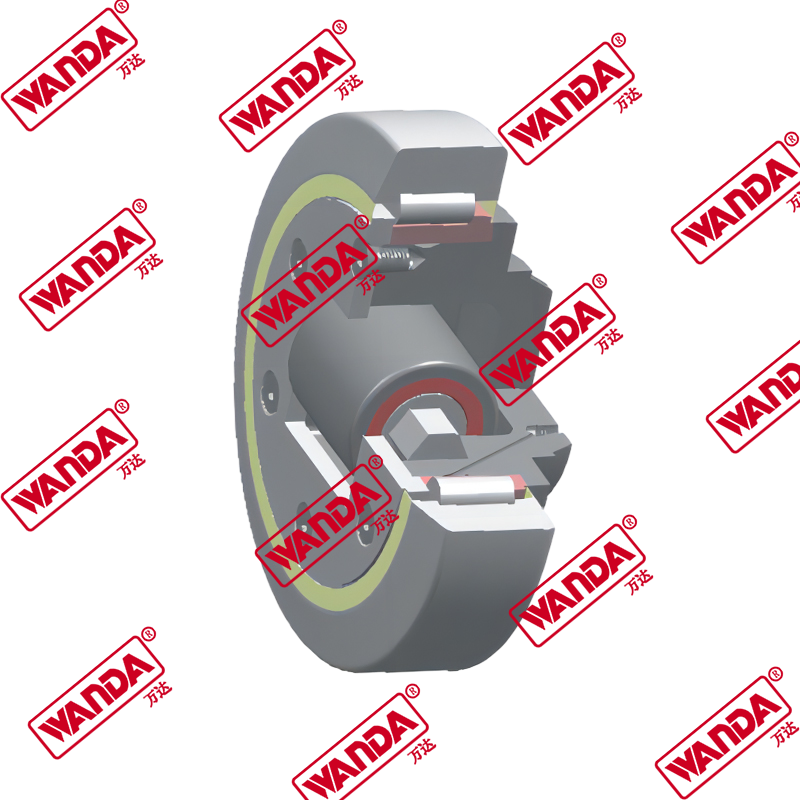

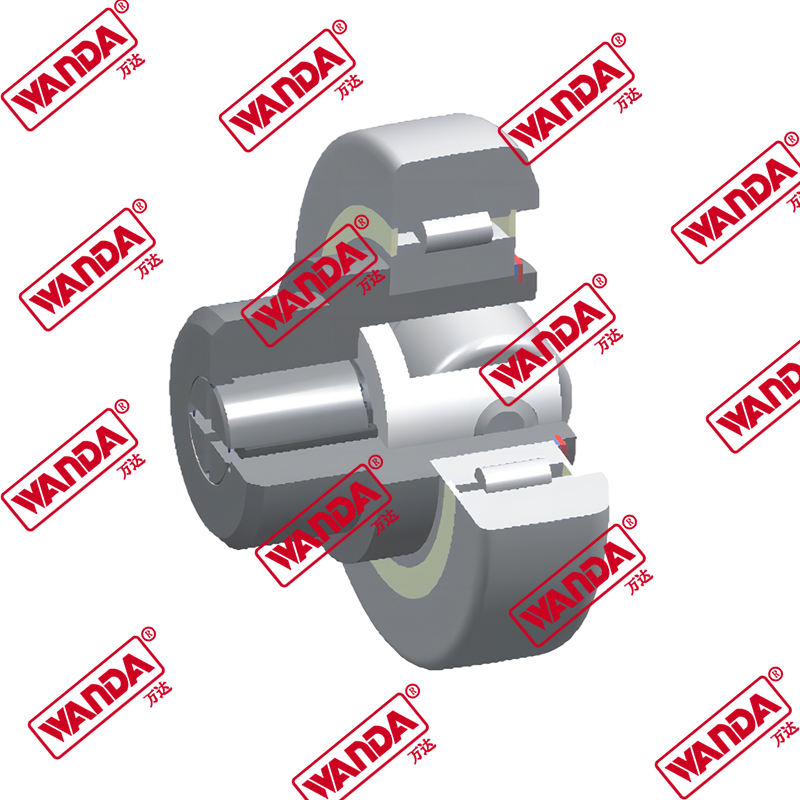

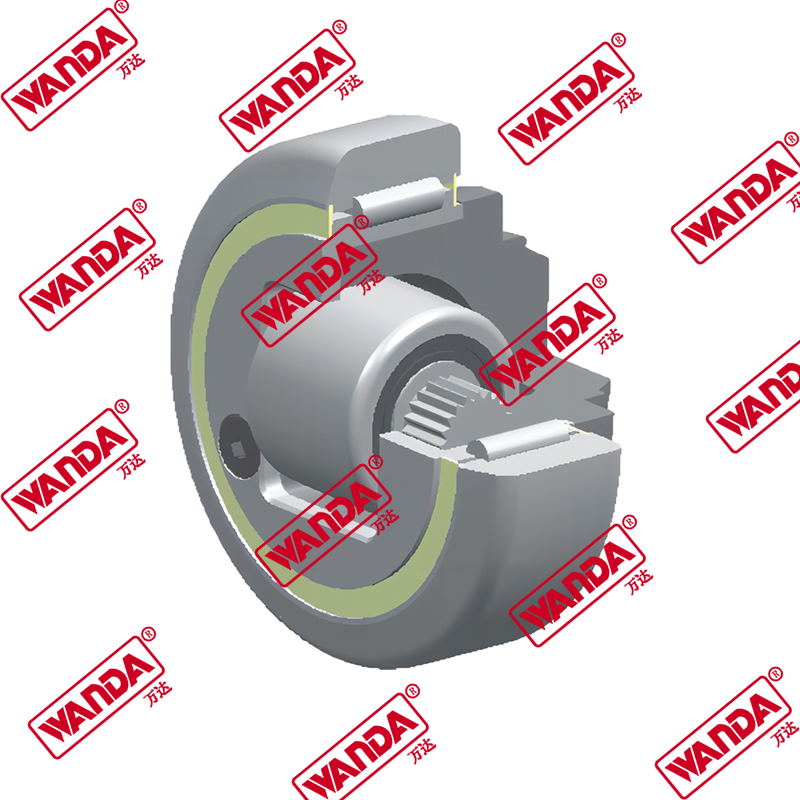

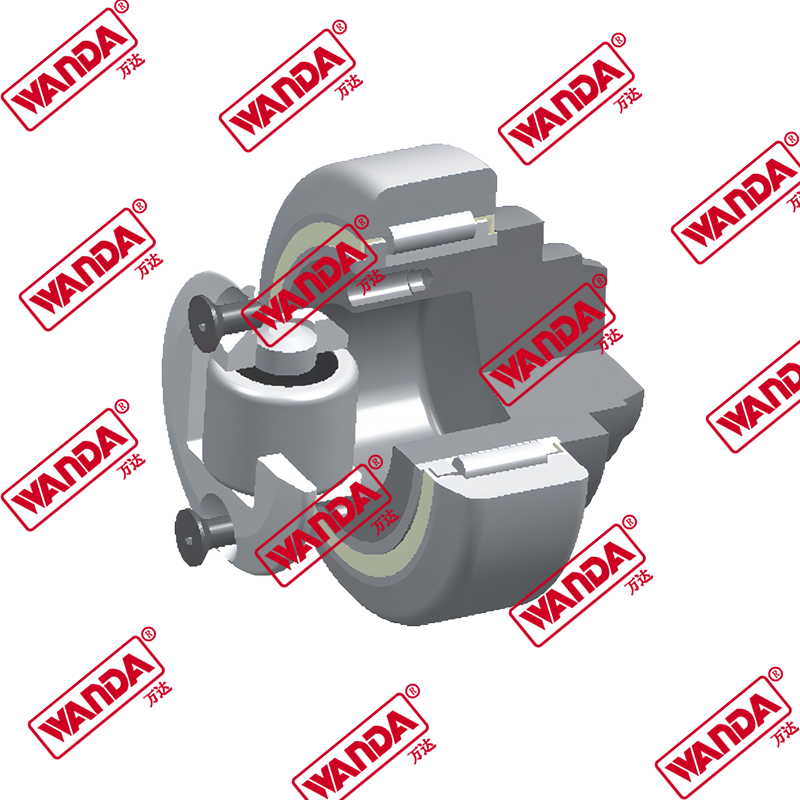

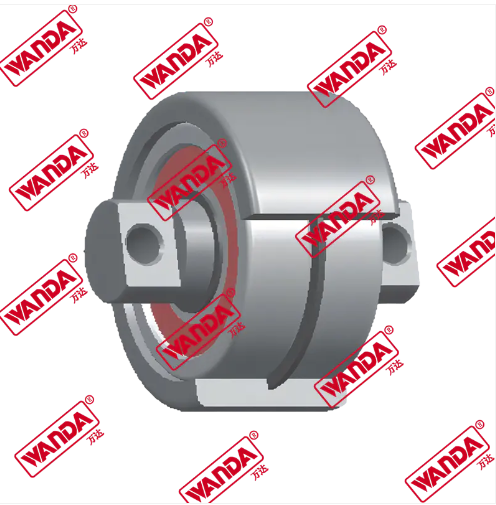

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

● Installation method of forklift mast bearingThe commonly used installation method of mast bearings...

In the high-stakes environment of material handling, the structural integrity of a forklift mast is dictated by the prec...

READ MORE

In the material handling industry, the structural integrity and smooth operation of a lifting system rely heavily on pre...

READ MORE

Selecting the right roller wheel chain is critical for ensuring the longevity, efficiency, and safety of countless mecha...

READ MORE

For over half a century, the reliable transmission of power in heavy machinery has hinged on a critical yet often overlo...

READ MORE