In busy warehousing and logistics centers, forklifts have become an indispensable tool for cargo handling with their high efficiency and flexibility. In the complex mechanical structure of the forklift, the gantry sprocket bearing plays a pivotal role as a key component in the chain transmission of the forklift gantry system. It not only carries the weight of the goods and equipment itself, but also ensures the stability and accuracy of the forklift in performing various tasks through a precise transmission mechanism. This article will explore in depth the support and transmission functions of the forklift gantry sprocket bearing and its importance in the work of the forklift.

1. Support and transmission: the dual mission of the sprocket bearing

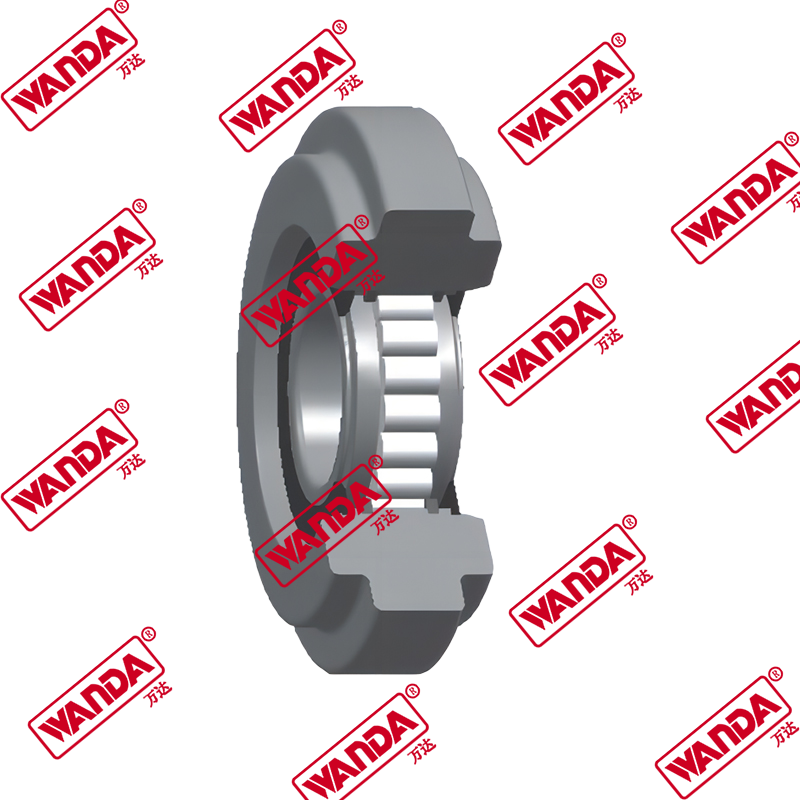

As a bridge connecting the oil cylinder and the gantry system, the core function of the forklift gantry sprocket bearing is support and transmission. When the forklift is lifting and lowering, the thrust generated by the oil cylinder is transmitted to the sprocket bearing through the chain, which in turn drives the gantry (fork frame) to move in the vertical direction. This process seems simple, but it actually contains complex mechanical principles and precise manufacturing processes. Sprocket bearings must be able to withstand huge loads, including the weight of the cargo, the weight of the equipment, and the impact force generated during dynamic operations, while maintaining structural integrity and transmission accuracy.

2. Load bearing: Challenges and responses

The diversity of forklift operating environments places extremely high demands on sprocket bearings. From lightweight small items to heavy bulk materials, forklifts need to have corresponding load-bearing capacity. As the key support point in this process, the sprocket bearing's material selection, structural design, and manufacturing process must all be strictly considered. High-strength alloy steel, precision raceway processing, and advanced heat treatment technology together form the basis for the high strength and high wear resistance of sprocket bearings. In addition, a reasonable lubrication system is also the key to ensure the long-term and stable operation of the sprocket bearing, which can effectively reduce friction loss and extend its service life.

3. Transmission accuracy: Guarantee of efficiency and safety

In forklift operations, the accuracy of the transmission system is directly related to operating efficiency and safety. The matching accuracy of the sprocket bearing and the chain, the clearance control inside the bearing, and the overall dynamic balance are all key factors affecting transmission accuracy. High-quality sprocket bearings ensure low noise, low vibration, and high position control accuracy during the transmission process through precision manufacturing and strict quality control. This not only improves the operating efficiency of the forklift, but also ensures the safety of personnel and goods at critical moments.

4. Stability and durability: Coping with complex working conditions

The working environment of forklifts is complex and changeable. From flat warehouse floors to rugged construction sites, sprocket bearings need to show extremely high stability and durability. By optimizing the bearing structure, enhancing material strength, and adopting advanced surface treatment technology, sprocket bearings can maintain stable performance under extreme conditions and resist corrosion, wear and fatigue damage. This stability and durability is an important guarantee for forklifts to continue to operate efficiently under various complex working conditions.

5. Technological innovation and future prospects

With the continuous advancement of forklift technology, the design of sprocket bearings is also constantly innovating. The application of lightweight materials, the development of intelligent lubrication systems, and intelligent bearings with integrated sensors are gradually becoming a new trend in the development of sprocket bearings. These innovations not only improve the performance and reliability of sprocket bearings, but also provide strong support for the intelligent and automated development of forklifts. In the future, sprocket bearings will become more intelligent and efficient, becoming an important driving force for the advancement of forklift technology.