1. Reduce steering resistance: upgrade the flexibility of forklift operation

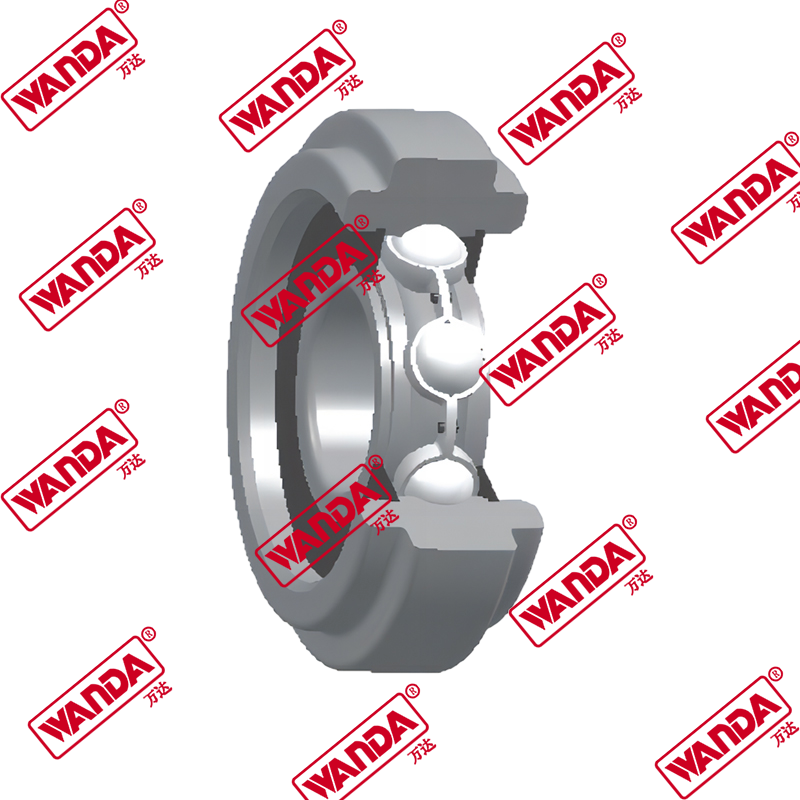

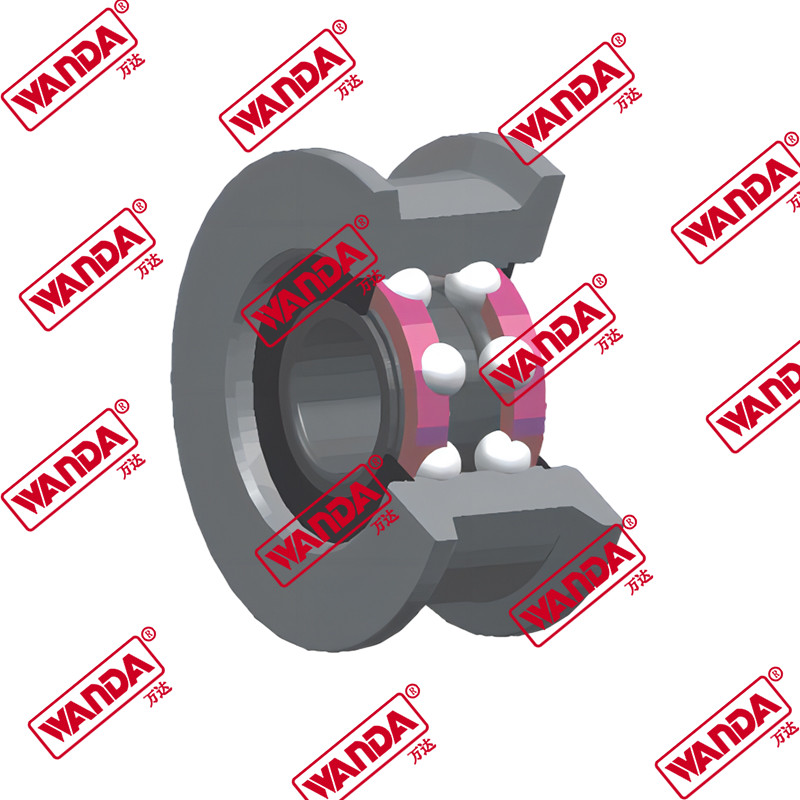

When performing tasks, forklifts often need to flexibly turn in narrow spaces, which requires forklifts to have not only strong power output, but also efficient steering systems. During the steering process of traditional forklifts, the direct contact between the wheels and the ground will generate a large friction force, which is the steering resistance. It not only increases energy consumption, but also may cause the steering to be not smooth enough and affect the operation accuracy. In order to overcome this problem, engineers designed a forklift side roller system.

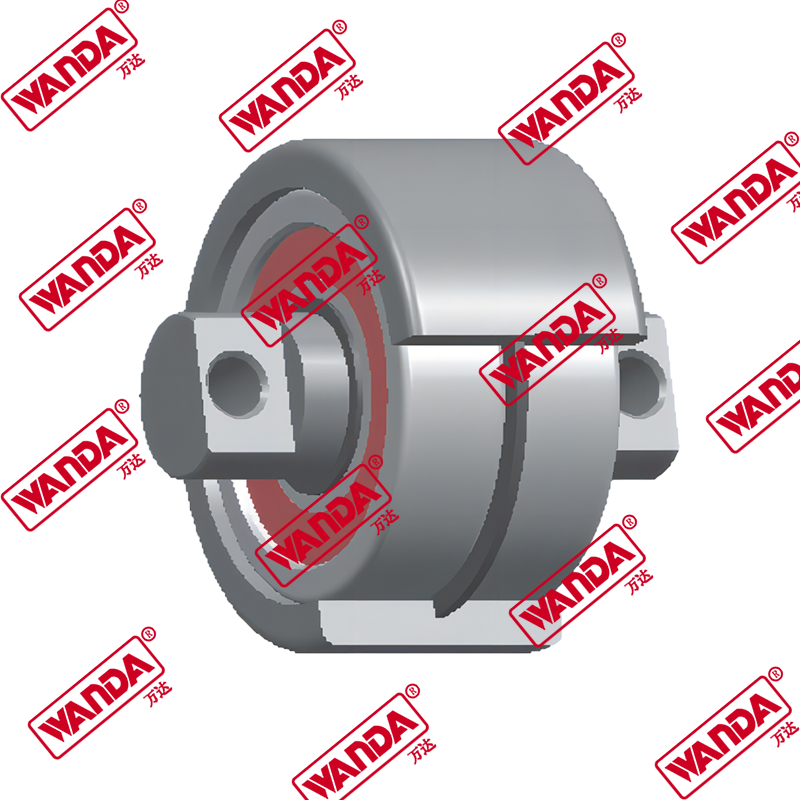

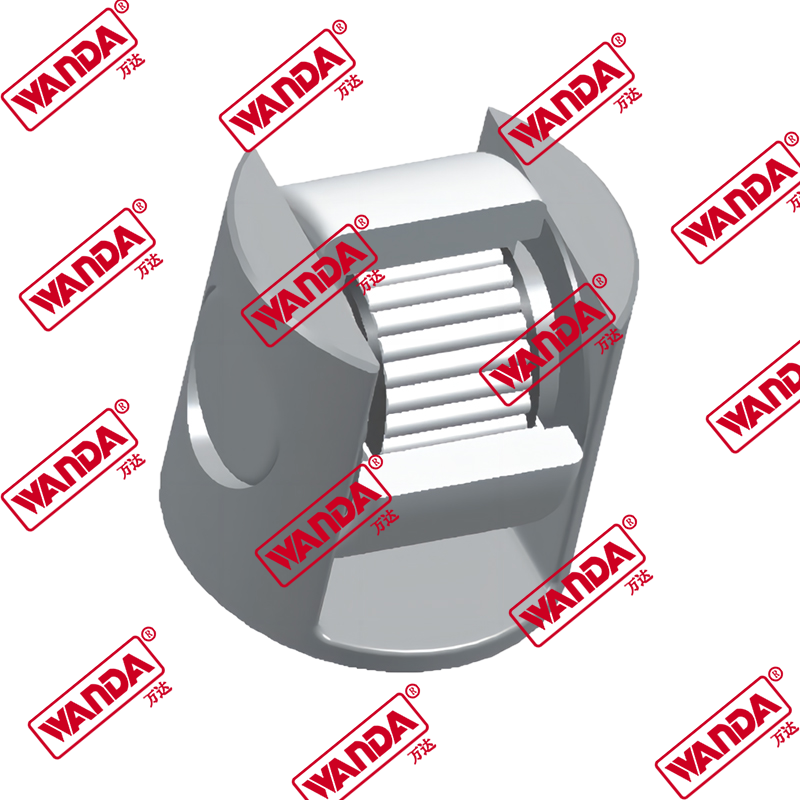

Forklift side rollers are usually installed on both sides of the front or rear of the forklift. When the forklift turns, the side rollers will contact the ground to assist in steering. These rollers are made of low-friction materials, which can effectively reduce the friction coefficient with the ground, thereby significantly reducing the torque required for steering, making the forklift steering easier and more comfortable. This design not only reduces the driver's operating burden and improves driving comfort, but more importantly, it greatly improves the steering response speed of the forklift, allowing the forklift to adjust its direction more quickly in complex environments and improve operating efficiency.

2. Enhanced stability: ensuring safety and intact goods

In a warehousing environment, forklifts often need to shuttle through narrow aisles between shelves, which places extremely high demands on the stability and safety of forklifts. When traditional forklifts turn quickly or move at high speed, they are prone to deviate from the route due to the shaking of the body, which not only threatens the safety of the driver, but also may cause damage to the goods. The application of forklift side rollers provides an effective solution to this problem.

The side rollers form a more stable support structure by increasing the contact points between the forklift and the ground. During the steering process, the lateral force generated by the contact between the side rollers and the ground helps to maintain the lateral stability of the forklift. Even in sharp turns or high-speed driving, it can effectively suppress the shaking of the body and ensure that the forklift travels smoothly along the predetermined route. This stability not only improves the adaptability of the forklift in complex environments, but also greatly reduces the risk of cargo damage caused by shaking, ensuring the safety and efficiency of logistics operations.

3. Comprehensive benefits: comprehensive optimization from operation to maintenance

The design of the forklift side rollers not only brings about a significant improvement in steering efficiency and stability, but also promotes the comprehensive optimization of forklift performance from multiple dimensions. First, reducing steering resistance means reducing energy consumption, which means reducing operating costs for long-term forklifts. Secondly, stable steering performance extends the service life of forklift components and reduces downtime caused by frequent adjustments or repairs. Finally, higher operational safety and cargo protection capabilities enhance companies' confidence in the use of forklifts and improve overall operating efficiency and customer satisfaction.