In the fast-paced world of modern logistics and warehousing, where every second counts and efficiency is paramount, the role of forklift chain sheaves has emerged as a crucial factor in enhancing operational performance and ensuring workplace safety. Recent advancements in forklift chain sheave technology have garnered significant attention within the industry, setting new standards for durability, functionality, and environmental compatibility.

Revolutionizing Material Handling with Advanced Chain Sheaves

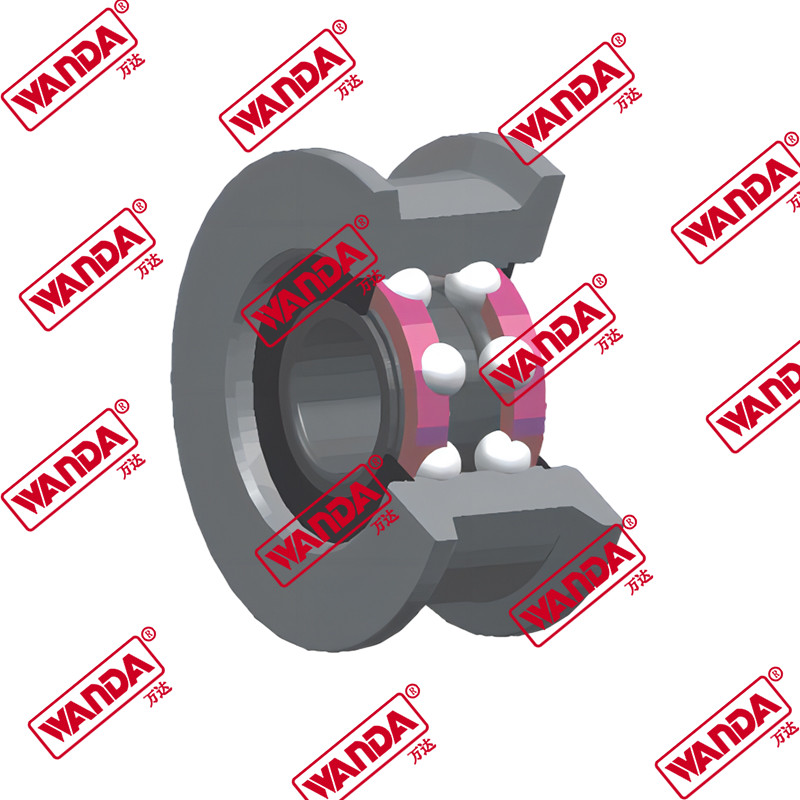

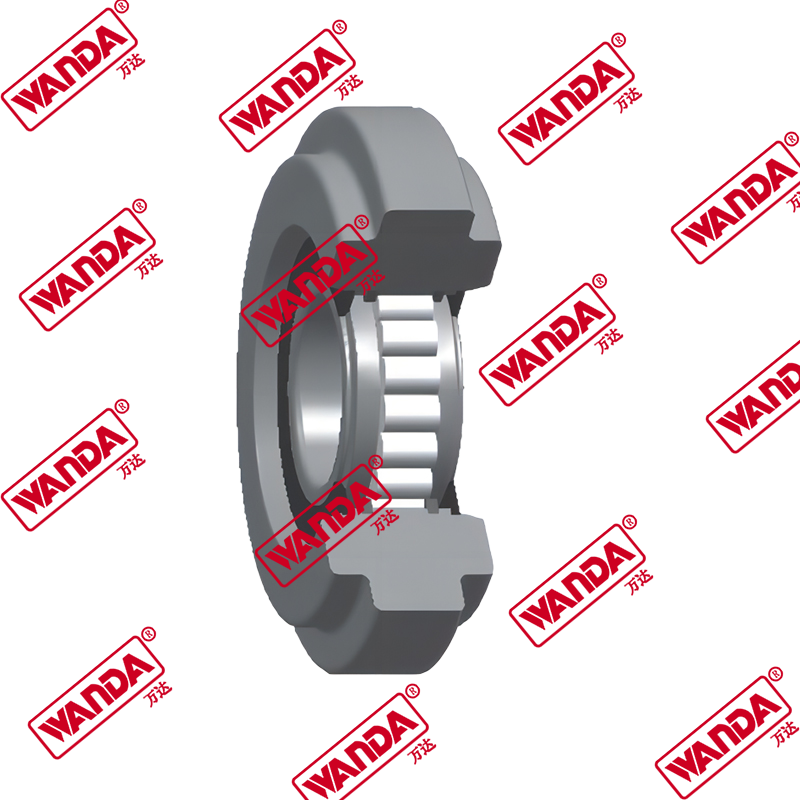

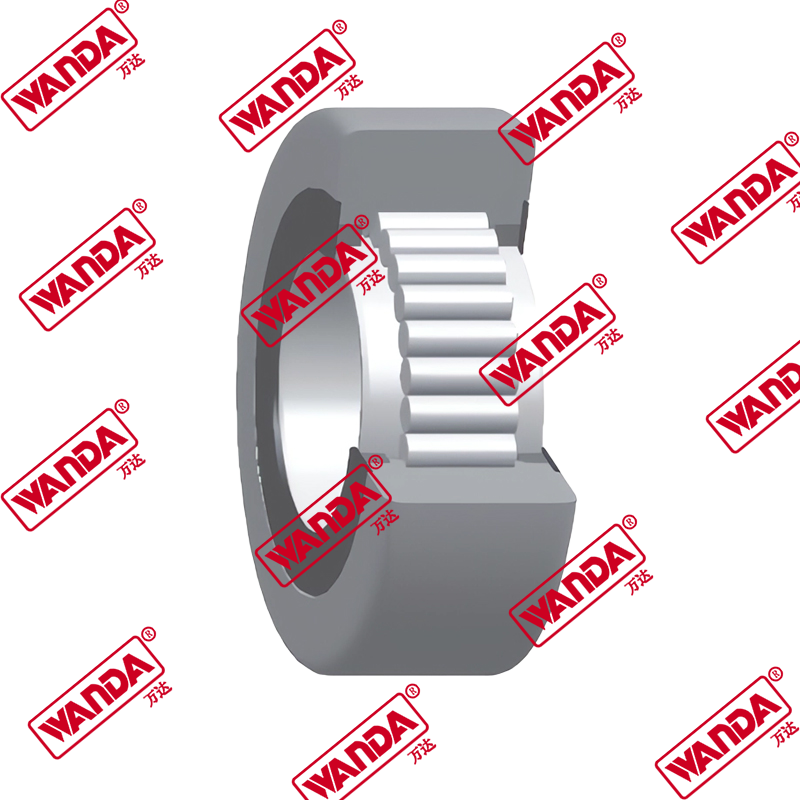

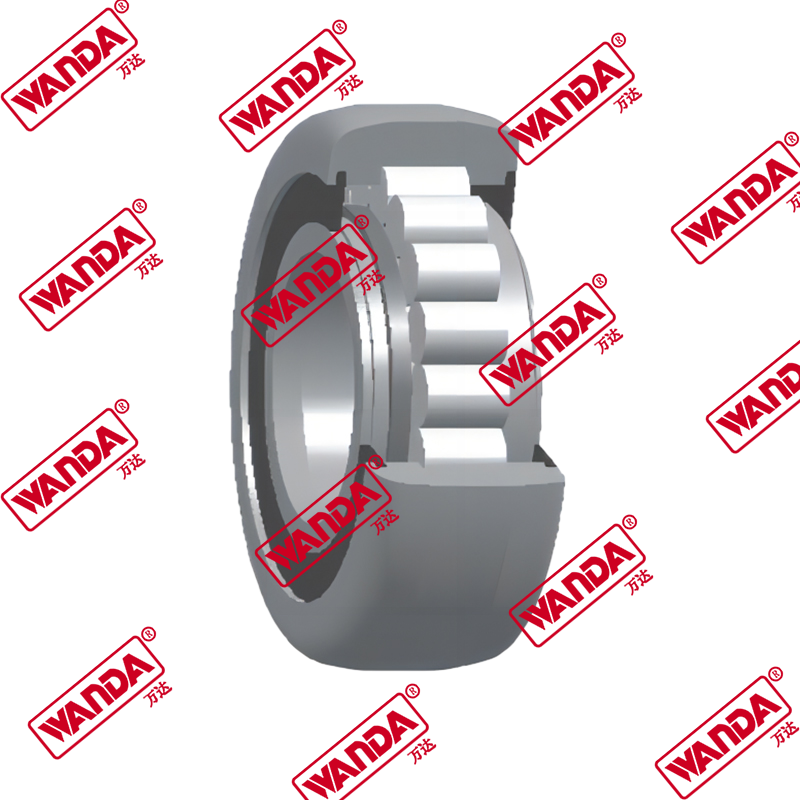

The traditional forklift chain sheave, a vital component that guides and supports the chains used in lifting mechanisms, has undergone a transformation to meet the demands of today's warehouses. Manufacturers are now incorporating cutting-edge materials and designs that not only increase the sheave's lifespan but also contribute to smoother, quieter, and more efficient lifting operations.

Durable Materials for Enhanced Durability

One of the most notable trends is the adoption of high-strength, wear-resistant materials for forklift chain sheaves. These materials, such as hardened steel alloys and specialized composites, significantly enhance the sheave's resistance to abrasion and fatigue, reducing maintenance costs and downtime. This not only benefits the warehouse's bottom line but also minimizes the environmental impact by prolonging the life cycle of equipment.

Design Innovations for Improved Performance

Design innovations have also played a pivotal role in elevating the performance of forklift chain sheaves. Engineers are designing sheaves with optimized profiles and geometries that reduce friction and wear, leading to smoother chain movement and reduced energy consumption. Additionally, some manufacturers are integrating self-lubricating features or using low-friction coatings to further enhance performance and extend service intervals.

Environmental Sustainability in Focus

In line with the global push towards sustainability, the forklift chain sheave industry is embracing eco-friendly practices. Manufacturers are focusing on reducing the environmental footprint of their products by using recyclable materials, minimizing waste during production, and optimizing designs to reduce energy consumption. This commitment to sustainability not only benefits the planet but also aligns with the values of many modern businesses looking to reduce their carbon footprint.

Smart Technology Integration

The integration of smart technology into forklift chain sheaves is another exciting development. By incorporating sensors and IoT (Internet of Things) capabilities, manufacturers can monitor the condition of sheaves in real-time, detecting potential issues before they escalate into costly failures. This predictive maintenance approach helps warehouses maintain optimal operational efficiency while minimizing unexpected downtime.

As the logistics and warehousing sectors continue to evolve, the role of forklift chain sheaves in driving efficiency and safety becomes increasingly significant. The industry's commitment to innovation, durability, and environmental sustainability ensures that these vital components will continue to evolve, meeting the challenges of modern warehousing and contributing to the overall success of businesses worldwide. With advancements in materials, design, and technology, the future of forklift chain sheaves looks bright, poised to revolutionize material handling for years to come.