In the rapidly evolving world of logistics and supply chain management, every component counts towards enhancing operational efficiency, reducing downtime, and promoting environmental sustainability. One such vital component that has garnered significant attention recently is the advancement in forklift bearings. These precision-engineered components, designed specifically for the demanding environments of warehouses and distribution centers, are undergoing a technological renaissance, transforming the way we move goods and materials.

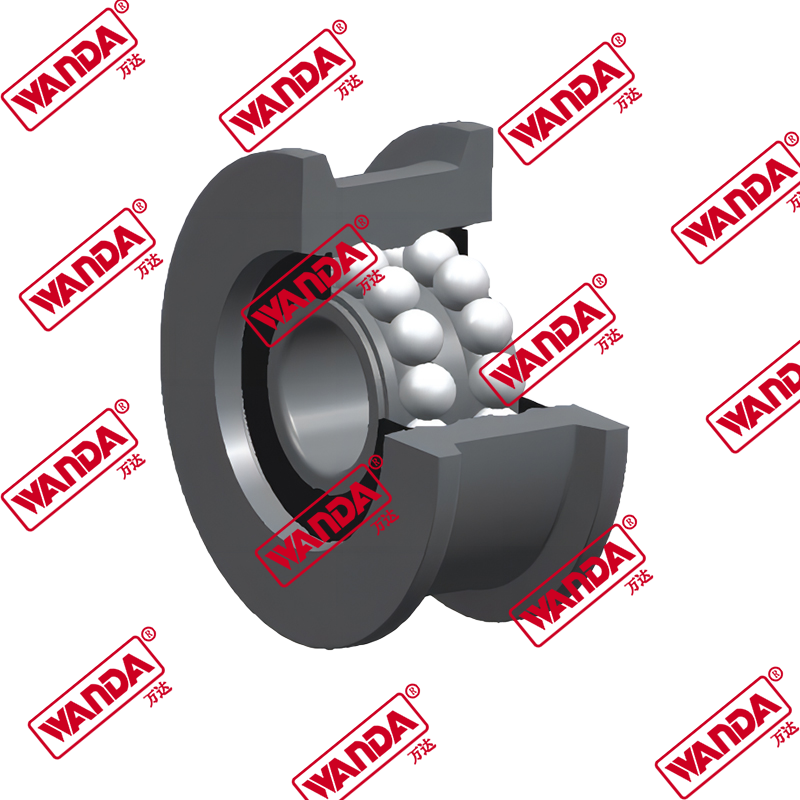

The Rise of Durability and Performance

With the increasing reliance on automation and robotics in the logistics sector, forklift bearings are facing unprecedented demands for durability, precision, and reliability. Manufacturers are investing heavily in research and development to create bearings that can withstand the rigors of continuous operation, heavy loads, and variable operating conditions.

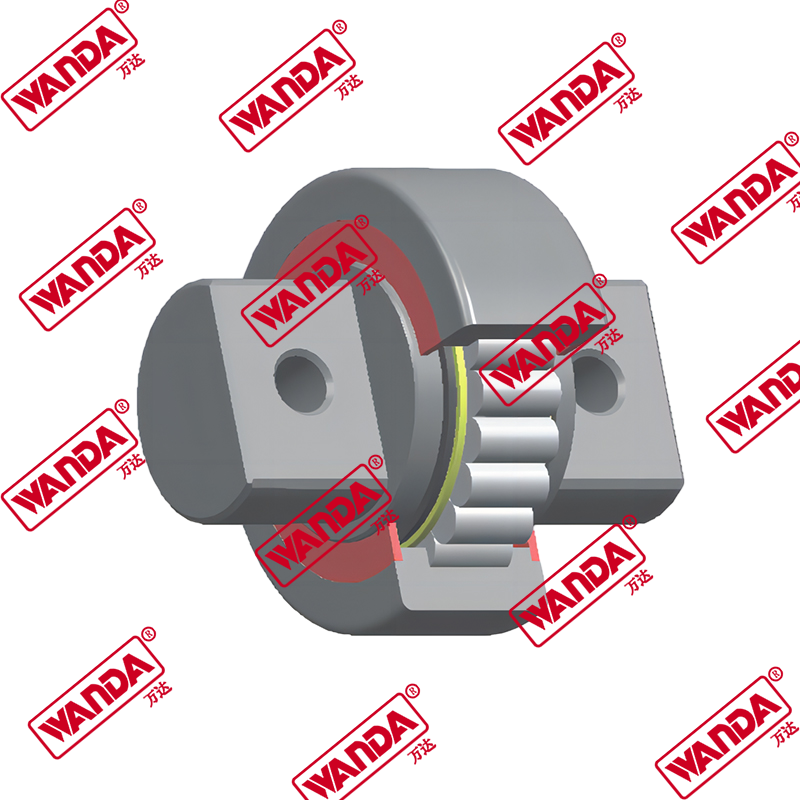

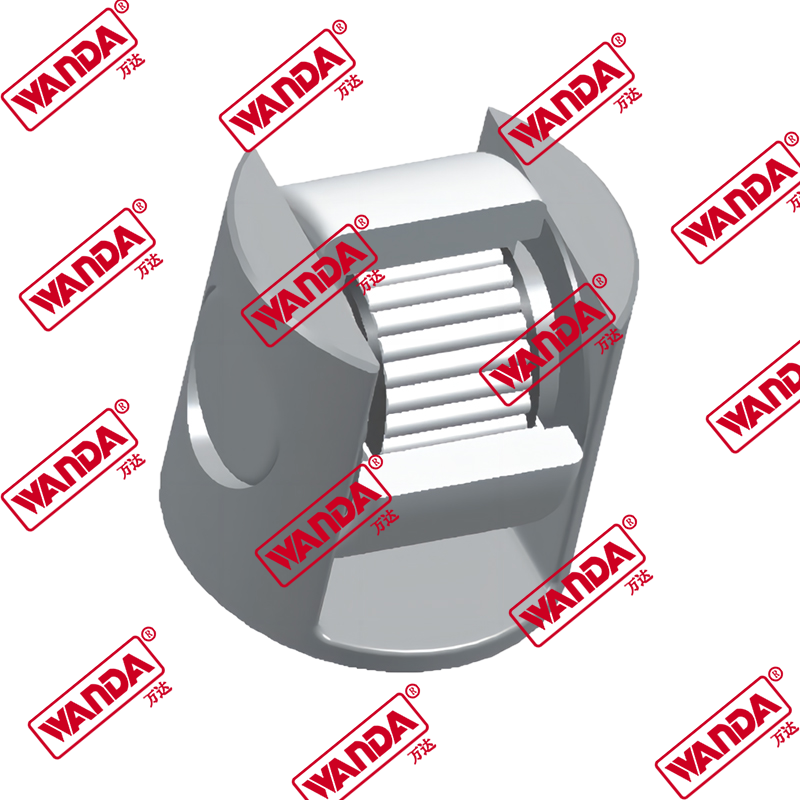

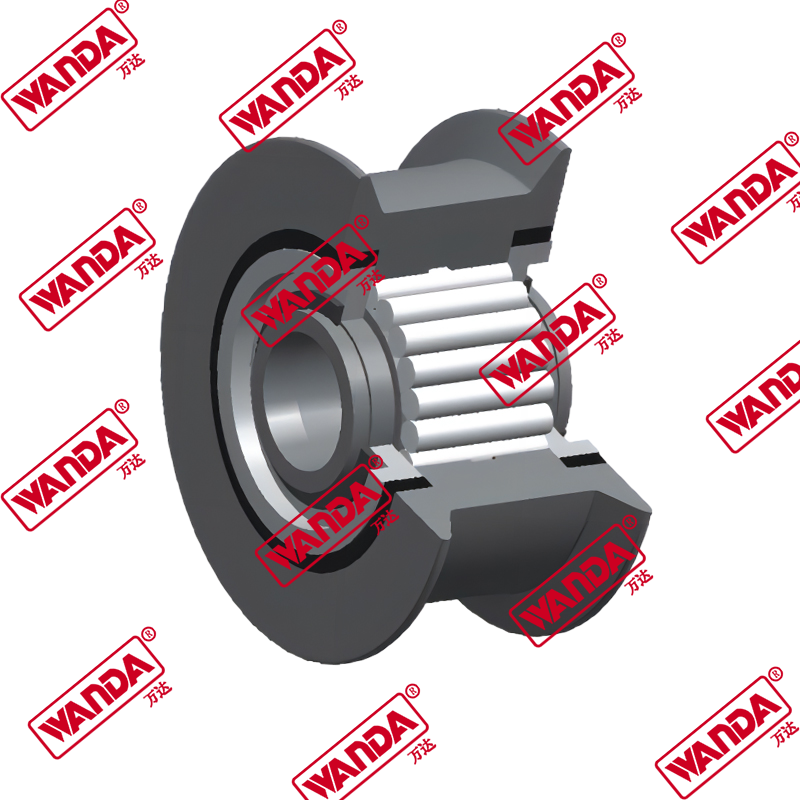

Innovative Designs for Enhanced Efficiency

Recent innovations in forklift bearing design include advanced materials, such as high-strength alloys and specialized coatings, that significantly improve wear resistance and extend bearing life. These designs also incorporate low-friction surfaces, reducing energy consumption and heat generation, which in turn leads to lower maintenance costs and improved overall forklift performance.

Sustainability at the Core

In line with the global push towards sustainability, manufacturers are developing eco-friendly forklift bearings that minimize environmental impact. This includes the use of recyclable materials, reduced packaging waste, and optimized production processes that consume less energy and emit fewer greenhouse gases. The longevity of these bearings also contributes to sustainability by reducing the need for frequent replacements, thereby minimizing waste generation.

Smart Bearings: The Future of Forklifts

The integration of IoT (Internet of Things) technology into forklift bearings is another groundbreaking development. Smart bearings equipped with sensors can monitor their own health, predicting maintenance needs before failures occur. This predictive maintenance approach ensures minimal downtime, maximizing operational efficiency and productivity. Moreover, real-time data analysis allows fleet managers to optimize workflows and identify areas for further improvement.

Case Study: Implementing Advanced Forklift Bearings

A leading logistics company recently upgraded its fleet of forklifts with the latest generation of innovative bearings. The results were impressive, with a reported 30% reduction in maintenance costs, 20% increase in operational efficiency, and a significant reduction in carbon emissions due to reduced energy consumption. This success story underscores the transformative power of advanced forklift bearings in modern supply chains.

As the logistics industry continues to evolve, the role of forklift bearings in driving efficiency, reliability, and sustainability cannot be overstated. The ongoing innovations in bearing technology, from material advancements to smart integration, are poised to revolutionize the way goods are moved and managed worldwide. By embracing these technological advancements, businesses can stay ahead of the curve, enhancing their competitive edge, and contributing to a more sustainable future.