In large warehousing facilities, the seamless movement of heavy goods such as machinery, equipment, and bulk raw materials is a daily necessity. This demands that the forklift's main rollers bear the weight of these loads while maintaining stable operation throughout the handling process.

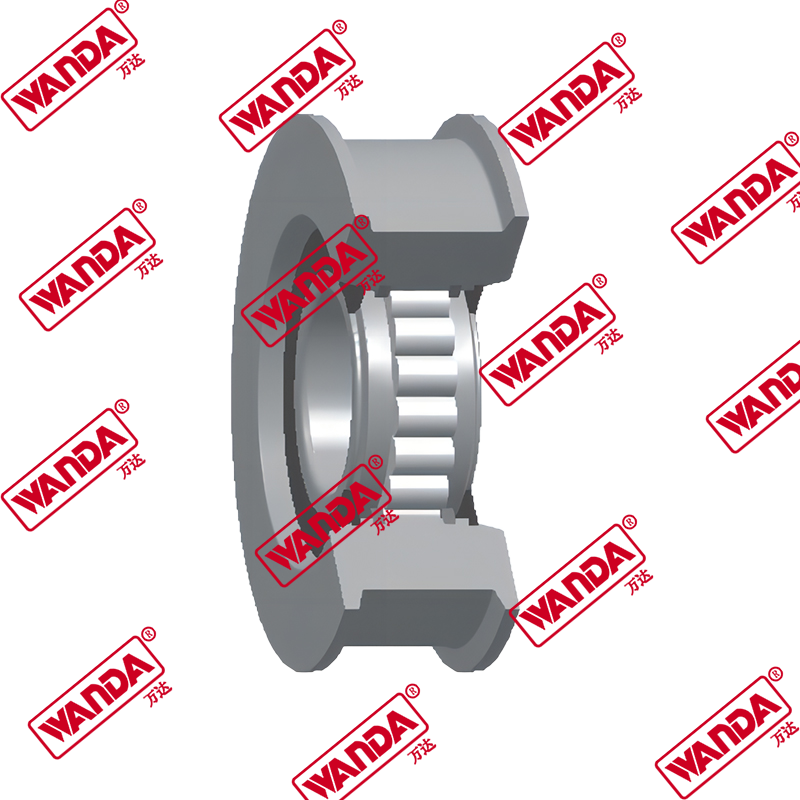

Modern forklift designs prioritize robustness and efficiency, with main rollers crafted from high-strength materials capable of withstanding substantial loads. These materials boast excellent compression and wear resistance properties, ensuring the longevity and stability of the rollers under demanding conditions.

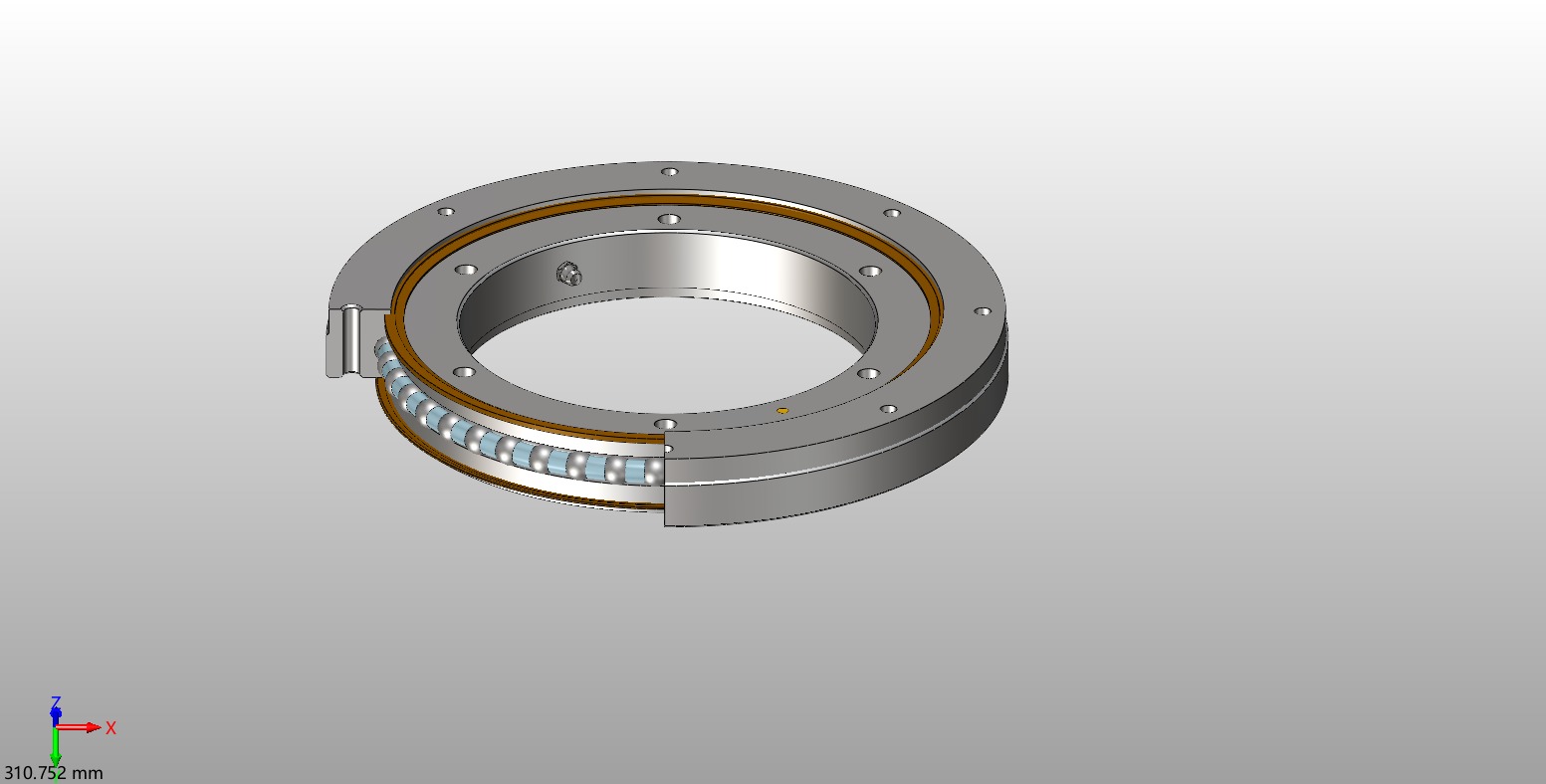

Furthermore, meticulous attention is given to the design of forklift main rollers to optimize their stability and balance. Precise calculations dictate the shape, size, and placement of the rollers, guaranteeing equilibrium and steadiness when handling heavy loads. Surface treatments are also applied to minimize friction and resistance, facilitating smoother and more efficient operation of the forklift.

Despite the inherent strength and stability of forklift main rollers, operational and maintenance considerations remain paramount. Operators must adhere to specifications, avoiding overloading or improper usage that could damage the rollers. Additionally, regular inspection and maintenance routines, including surface cleaning and timely replacement of worn rollers, are essential to sustain their long-term performance and reliability.

In selecting forklift main rollers for handling heavy goods in large warehousing facilities, prioritizing load-bearing capacity and stability is imperative. Equally crucial is the adherence to proper operation and maintenance practices to uphold the rollers' performance and ensure uninterrupted workflow efficiency.