The installation of wind turbines in remote and high-altitude locations presents unique challenges that demand solutions tailored to simplify the process. In response to these demands, combined bearings emerge as versatile components equipped with features conducive to easy installation in such specialized working environments.

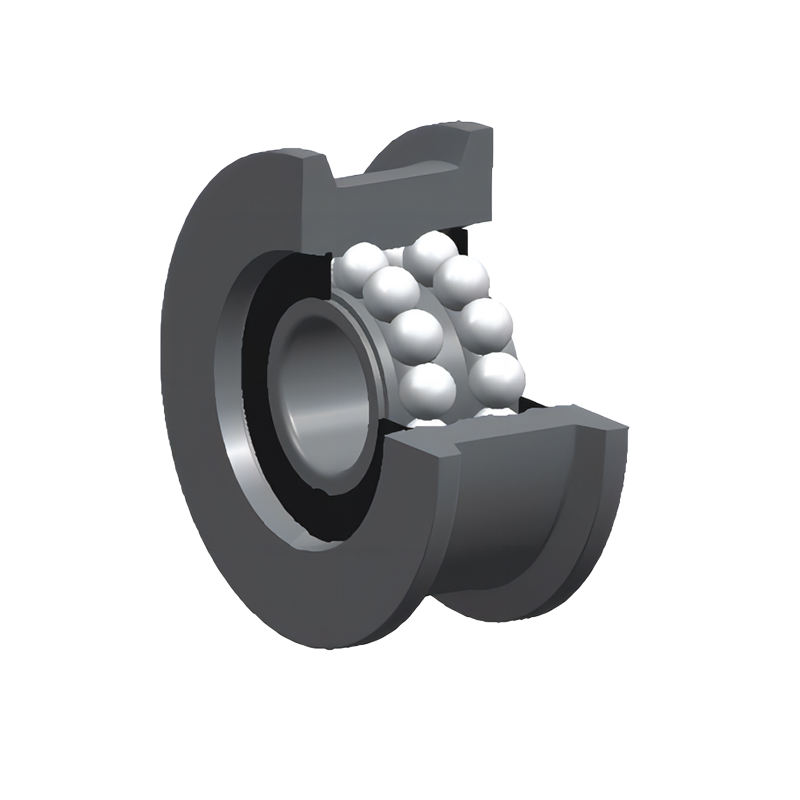

Primarily, the modular design of combined bearings streamlines installation procedures significantly. This design allows for swift assembly and disassembly of various components, reducing installation steps and tool requirements. Consequently, not only does installation efficiency improve, but the likelihood of errors during the process diminishes as well.

Moreover, combined bearings often boast standardized interfaces and mounting holes, facilitating seamless integration with other wind turbine components. By adhering to these industry-standard designs, the need for extensive adjustments and adaptations during installation is minimized, enhancing installation accuracy and reliability.

Furthermore, the lightweight and compact nature of combined bearings further contributes to their suitability for installation at high altitudes. Their reduced weight alleviates strain on installers, while their compact structure conserves installation space, enabling smooth execution even within confined spaces at elevated heights.

The easy installation characteristics inherent in combined bearings make them adept at meeting the installation demands of wind turbines in remote and high-altitude settings. This not only bolsters installation efficiency but also drives down installation costs, thereby ensuring the seamless operation of wind turbines. However, adherence to installation specifications and safety protocols remains paramount during the installation process to uphold installation quality and safeguard personnel.